- 329

- 52

- 28

- Location

- Bakersfield, CA

In the process of replacing my torn axle boots, I decided to replace my spindle and king pin bushings. Being that the truck is 50+ years old, I had no idea how long they have been in there. Since I was there anyways, I chose to replace the bushings in the spindle along with the king pin bushings. You know, to eliminate this messy process for a while.

Since the old bushings (TM=bearings) came off in the "holders", or as the TM refers to them as "Sleeves", I decided to press in the new bushings into the sleeves, then install the assembly onto the knuckle. This proved to be quite difficult as the tolerances between the new bushings and the king pins was next to nothing. Understandably they are new, and should be this way, I am concerned with the installation. I have already boogered up a few new bushings and new ones are on the way

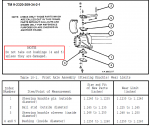

The TM (-24-1) instructs to install the lower assembly first, then the uppers on each side, then the steering arm. Even still, with brand new bushings, I had a hard time installing these with the bushings already pressed into the sleeves.

The TM does not describe prior pressing in of the bushings, it does say, "Install the sleeve (lower), bearing and spacer on the left and right knuckle", then completes the process with the top assemblies.

Is it recommended to install the new bushings on the vehicle? I.E. without first prior pressing them into the sleeves? I think this would actually be easier, with anti-seize and some sort of clamp press, like how a ball joint press or C-clamp works. I think the TM is misleading here, and almost sounds like it should be done as such, of course without the mechanical assistance of a press.

I've checked my tolerances on the king pins and they are within spec, not out of round, 1.124" OD. I've measured in several places on the caliper. All the sleeves are the same size, 1.127" ID. If you add everything up, it is .000 to .001" tolerance!

Do you need to "open up" or burnish the bushings and/or pins prior to install? The TM does not describe this but previous posts by some other folks on here did mention something to this. It could have been on a different vehicle. Obviously the same question would apply to the spindle bushings. The ride super tight on the axle and I'm afraid they (king pin and spindle bushings) will be damaged upon installation.

Perhaps this has been posted before, but the ones I've seen and searched it barely touches on the subjects without having the issues I have when others have done the boot installs.

I'm about ready to just put the old bushings back in, bearings are good, alignment is good, but the right tire has always worn funny, and want to defer going back into the knuckles for a while. I didn't think it would be that difficult of a job to get it taken care of.

Any help is appreciated. Thank you.

Mike

Since the old bushings (TM=bearings) came off in the "holders", or as the TM refers to them as "Sleeves", I decided to press in the new bushings into the sleeves, then install the assembly onto the knuckle. This proved to be quite difficult as the tolerances between the new bushings and the king pins was next to nothing. Understandably they are new, and should be this way, I am concerned with the installation. I have already boogered up a few new bushings and new ones are on the way

The TM (-24-1) instructs to install the lower assembly first, then the uppers on each side, then the steering arm. Even still, with brand new bushings, I had a hard time installing these with the bushings already pressed into the sleeves.

The TM does not describe prior pressing in of the bushings, it does say, "Install the sleeve (lower), bearing and spacer on the left and right knuckle", then completes the process with the top assemblies.

Is it recommended to install the new bushings on the vehicle? I.E. without first prior pressing them into the sleeves? I think this would actually be easier, with anti-seize and some sort of clamp press, like how a ball joint press or C-clamp works. I think the TM is misleading here, and almost sounds like it should be done as such, of course without the mechanical assistance of a press.

I've checked my tolerances on the king pins and they are within spec, not out of round, 1.124" OD. I've measured in several places on the caliper. All the sleeves are the same size, 1.127" ID. If you add everything up, it is .000 to .001" tolerance!

Do you need to "open up" or burnish the bushings and/or pins prior to install? The TM does not describe this but previous posts by some other folks on here did mention something to this. It could have been on a different vehicle. Obviously the same question would apply to the spindle bushings. The ride super tight on the axle and I'm afraid they (king pin and spindle bushings) will be damaged upon installation.

Perhaps this has been posted before, but the ones I've seen and searched it barely touches on the subjects without having the issues I have when others have done the boot installs.

I'm about ready to just put the old bushings back in, bearings are good, alignment is good, but the right tire has always worn funny, and want to defer going back into the knuckles for a while. I didn't think it would be that difficult of a job to get it taken care of.

Any help is appreciated. Thank you.

Mike