Hi all.

To start with, thank you for the existence of this forum. I haven't been around here too long or spent much time in the other subforums but there seems to be a very high signal to noise ratio within the FMTV community, and a number of very knowledgeable people willing to share and help. I hope to be able to eventually contribute in that manner as well. In the meantime, a rambling introduction and project statement follows. Feel free to ask questions or point out things where I may need some re-direction.

After spending ~2 years of casually vacationing throughout the north- and south-west US in a minimally converted EB E350 cargo van (we're not "vanlifers" or what have you), my wife and I were ready to move on. We've had bumper pull and slide-in/truck campers before and while we enjoyed them, they had compromises we weren't fond of and didn't have the durability or overall storage capacity we desire. With our time with all of these various vehicles, we developed our list of "wants" for what our ultimate RV would be: stand up height (I'm 6' 2"), dedicated bed space, reasonable kitchen/galley, full bath, lots of storage, and all wheel drive. We came up with a variety of vehicular options but based on budget goals (sorry Earthroamer), we decided that a full size 4x4 pickup with our own box outfitted in the manner we sought was our strongest play. We started looking.

And I couldn't find a rig.

Well, I could find them but... We had picked a ~$20k budget point for the base vehicle, and nothing in that ballpark was terribly attractive. I wanted diesel but not a 6.0 Powerstroke, and any of the Cummins that were in that range were 300K or higher mileage and looked it on the inside. I couldn't bring myself to jump on any of those. I also couldn't bring myself to jump to the ~$35k level to acquire a base vehicle in the condition we desired. I would occasionally (twice, three times maybe, over 16 months?) find a decent offering, but they were gone before I could get there- including the one where I said I want it and will be there in the morning (was out of town) and it got sold that evening.

But I always knew what my dream rig would be though: a 6x6 with high speed gears and a big box on the back. I also knew this would never happen for a couple of reasons-

So, I kept cruising Craigslist, etc... looking for my reasonable mileage, one ton, 4x4 pick up... ...until this happened.

I would ply CL for LMTV search terms occasionally, and one night this past June, staring back at me from the screen was a 2000 M1088A1, about ~30 minutes away, with a clean bill of health from CAT of Portland, a new full set of 7 tires, a set of snow chains, and HIGH SPEED GEARS INSTALLED. No auction. No transport hassles. I could see/touch/sit in/test drive it!

I called. It was true. The seller bought it to build up but his wife wanted to travel now, so they bought a finished rig (gorgeous!) and were moving this one out. I set up to see it the next day with my wife. Test drive went great- it had things which needed some attention but I was pretty sure I could take care of them. We took a few minutes to chat about it and decided we'd do it. We left a deposit, came back the next day with a check, and drove it home!

On the way home from picking up:

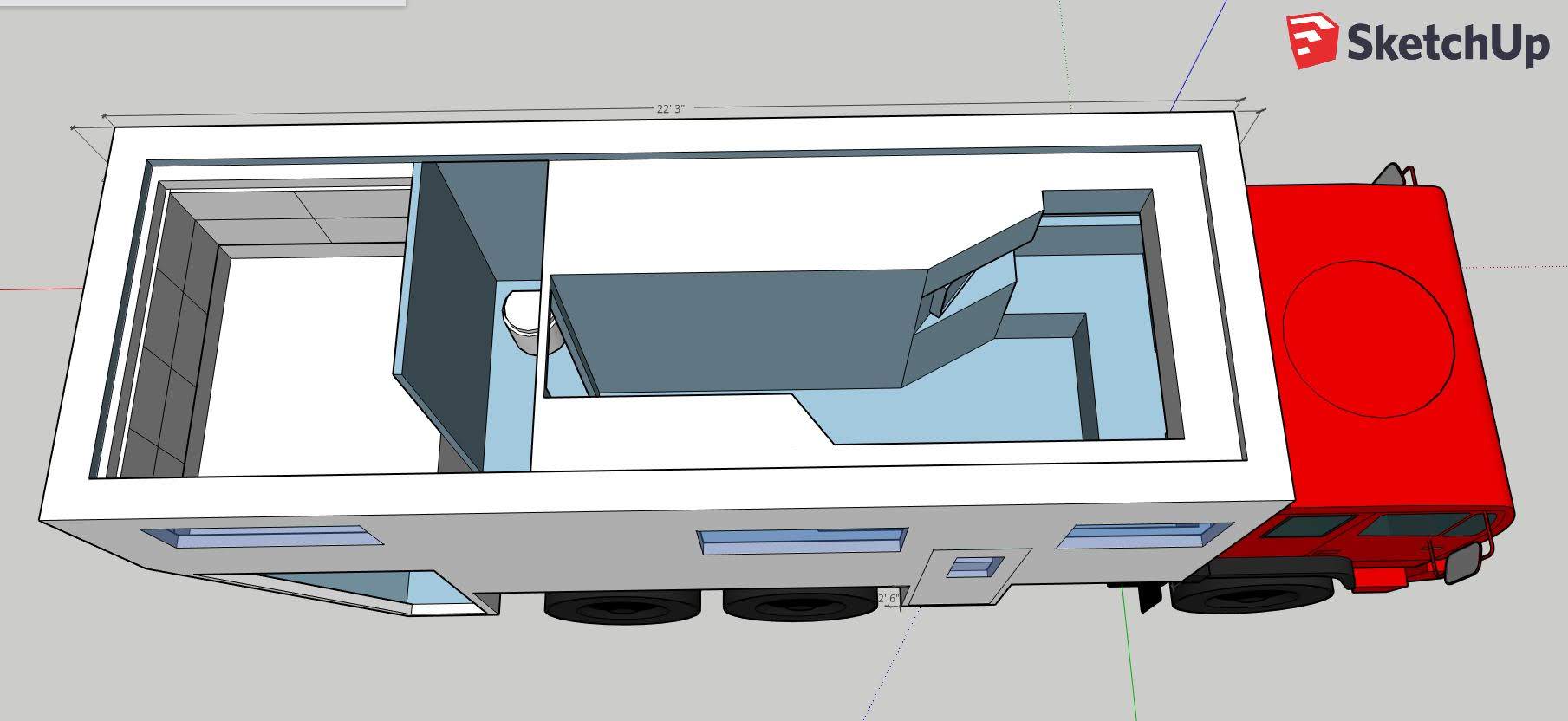

As for what we intend to do with it, the current plan is something along the lines of this:

Interior-ish view:

With this becoming our reality, we have also added a cab to box pass-thru to the list of wants, which necessitates removal/relocation of a bunch of stuff. Another addition to the design brief is internal storage for spare tire and bikes. We want to have as little as possible in view and/or getting dusty or wet. We have touring kayaks we also want to keep with us on some trips and by controlling the total height of the box, I think we can get away with this (~13' 2" with the boats on the roof). I hope to make them the only gear stored on the exterior.

This will be a massive project. I have probably done all of the elements required for it, but just not all for one single project. Thanks to those who have answered the questions I have already posted. There are more coming!

To start with, thank you for the existence of this forum. I haven't been around here too long or spent much time in the other subforums but there seems to be a very high signal to noise ratio within the FMTV community, and a number of very knowledgeable people willing to share and help. I hope to be able to eventually contribute in that manner as well. In the meantime, a rambling introduction and project statement follows. Feel free to ask questions or point out things where I may need some re-direction.

After spending ~2 years of casually vacationing throughout the north- and south-west US in a minimally converted EB E350 cargo van (we're not "vanlifers" or what have you), my wife and I were ready to move on. We've had bumper pull and slide-in/truck campers before and while we enjoyed them, they had compromises we weren't fond of and didn't have the durability or overall storage capacity we desire. With our time with all of these various vehicles, we developed our list of "wants" for what our ultimate RV would be: stand up height (I'm 6' 2"), dedicated bed space, reasonable kitchen/galley, full bath, lots of storage, and all wheel drive. We came up with a variety of vehicular options but based on budget goals (sorry Earthroamer), we decided that a full size 4x4 pickup with our own box outfitted in the manner we sought was our strongest play. We started looking.

And I couldn't find a rig.

Well, I could find them but... We had picked a ~$20k budget point for the base vehicle, and nothing in that ballpark was terribly attractive. I wanted diesel but not a 6.0 Powerstroke, and any of the Cummins that were in that range were 300K or higher mileage and looked it on the inside. I couldn't bring myself to jump on any of those. I also couldn't bring myself to jump to the ~$35k level to acquire a base vehicle in the condition we desired. I would occasionally (twice, three times maybe, over 16 months?) find a decent offering, but they were gone before I could get there- including the one where I said I want it and will be there in the morning (was out of town) and it got sold that evening.

But I always knew what my dream rig would be though: a 6x6 with high speed gears and a big box on the back. I also knew this would never happen for a couple of reasons-

- Don't meet your heros- I had never touched one, never mind sat in or driven one. Would I even like it?

- I was too chicken to roll the dice and pick one up from an auction.

- I was too cheap to pay the $'s at a flipper (despite understanding the service they provide)

- The wife had never seen, touched, or sat in one either, and despite saying she was OK with the idea, I didn't want to commit her to it.

- Having done a little homework, I understood that high speed gears are already a fairly tough find, even more so if you need 3 sets for a 6x6.

So, I kept cruising Craigslist, etc... looking for my reasonable mileage, one ton, 4x4 pick up... ...until this happened.

I would ply CL for LMTV search terms occasionally, and one night this past June, staring back at me from the screen was a 2000 M1088A1, about ~30 minutes away, with a clean bill of health from CAT of Portland, a new full set of 7 tires, a set of snow chains, and HIGH SPEED GEARS INSTALLED. No auction. No transport hassles. I could see/touch/sit in/test drive it!

I called. It was true. The seller bought it to build up but his wife wanted to travel now, so they bought a finished rig (gorgeous!) and were moving this one out. I set up to see it the next day with my wife. Test drive went great- it had things which needed some attention but I was pretty sure I could take care of them. We took a few minutes to chat about it and decided we'd do it. We left a deposit, came back the next day with a check, and drove it home!

On the way home from picking up:

As for what we intend to do with it, the current plan is something along the lines of this:

Interior-ish view:

With this becoming our reality, we have also added a cab to box pass-thru to the list of wants, which necessitates removal/relocation of a bunch of stuff. Another addition to the design brief is internal storage for spare tire and bikes. We want to have as little as possible in view and/or getting dusty or wet. We have touring kayaks we also want to keep with us on some trips and by controlling the total height of the box, I think we can get away with this (~13' 2" with the boats on the roof). I hope to make them the only gear stored on the exterior.

This will be a massive project. I have probably done all of the elements required for it, but just not all for one single project. Thanks to those who have answered the questions I have already posted. There are more coming!

Last edited: