MIDDLEMAN

Member

- 52

- 8

- 8

- Location

- Arlington/Washington

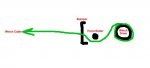

I have had the truck for about three weeks since the purchase from GP. Great truck so far. I have heard the winch may not even work but it looks complete and from the looks of the fair lead main roller, it has little use. Before I even engage the PTO I figure I should drain the Hyd. fluid tank, its full but when I loosened the fill cap fluid started to come out and it smelled like hydraulic fluid but was a little rusty looking. Bought 10 gallons of new at Costco and a new filter. Any thoughts or pre-test suggestions out there?