Good morning and thanks for the post! The batteries on this set are less than a year old and were charged completely over the past couple days. It is cranking faster now than I have started and ran it with before, and is still showing ~25.2 volts after multiple cranking events. So I do not believe batteries or cranking speed are the problem.

This set sounds different from the 806, but I have no experience with those. There is a solenoid style lift pump to fill the day tank, and I have verified full fuel flow to the inlet of the injection pump as stated above. However there is still a charge pump inside the roosamaster stanadyne injection pump

(Never seen one go bad) that I don't know how to check separate from the main injection pump.

As far as I can tell, there is no mag pick up on this set.

(correct. If it was a MEP-015A, it would have a mag pickup.) It picks up speed from the speed switch on the opposite side of the engine from the injection pump, and I am getting power through the appropriate circuits of it that send power to the solenoid on the injection pump. And the way I think about it (which could be wrong) when I applied the 24v to the injection pump solenoid, that should essentially bypass all safety systems on the set and make it run if it has fuel, right?

(Correct) I set the throttle at what gave it 60 Hz last time I was there and marked it to ensure it wasn't tinkered with, which I think are the only inputs to that pump besides the gear train and fuel.

One thing I should have mentioned last night, I checked the fuel drain out the top of the injection pump yesterday and it was bone dry. I tried to manually fill that line with a funnel from where it dumps back into the top of the day tank, but it made no difference. Makes me think that the solenoid may be clicking but whatever mechanism it moves in the pump itself may be stuck shut or at least sticky and not free.

View attachment 898721

1. Turn on the set to the run position. Dont start it, just put the S2 in the run position.

2. Put the S7 in the up position. You should hear the fuel pumps run. Put your hand on both of them to insure that they are indeed pumping.

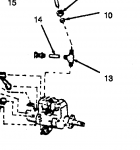

3. Look at the IP. On top, is a "T", item 13 in this picture. Break the line at the top of item 13. Do you get fuel out?

4. If so, then open the drain on the IP. Get fuel out?

5. There is a check valve there. I think its in the "T", or a fitting below the "T". That needs to be checked also. Dont just break the glass ball in it. Remove the check valve and soak it in something to eat the lacquer, holding the check valve closed. If you are not getting fuel to the IP, it aint never gonna start.

Oh and since I did not specifically say it before, all fault lights work with the test switch and the only one on during my testing is the low oil pressure, which is overridden by holding the start switch to 'start'.