Mep-805b No power to adc100-24 injection pump actuator. ESD5551 output power failure. Solution

Hello all. This will probably be my only post as I am rarely on the internet. I wanted to stop by and contribute as I have gained a ton of information from this forum over the past week.

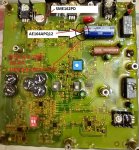

I purchased a used non-running MEP805b unit a couple of weeks ago. It was advertised as needing a mechanical fuel pump. No problem. It arrived, we put one in and it didn’t fire. The power supply light on the ESD5551 “Speed Control Unit” would not light up. This told me the unit was not getting power in or out. The Actuator light would not light at all when turning the engine over. This light should flash for about 3 seconds when starting, even if it doesn’t start. I tested voltage to the ADC100-24 injection pump actuator and it was not getting power. I was able to run 24v from one of the lights on the control panel to the injection pump and it started. You can hear it click when powered. DON’T DO THIS for more than 10 seconds as the speed is not governed. This told me the pump system was fine and it was getting fuel. I was able to trace the issue back to the ESD5551 board. Attached is a photo that shows the two components that were replaced with part numbers. About 70 cents. This restored power to the injection pump and the machine is running now. I still have some tuning work to do but it starts and runs. Parts were purchased from the guys at westfloridacomponents. Other cap suppliers will have the same products. WFC helped us cross reference part numbers making this project possible.

Notes: Try replacing one component at a time. They both may not be bad. Replacing these components should be done by a skilled electronics tech with a good hot air station and solder iron. The silicone epoxy does not melt. It will have to be picked / scraped off. The clear epoxy can be replaced with MG Chemicals 422b compound.

If anyone has dead ESD5551 units laying around I would be interested in them. Please PM me.

Off to solve my dead computer mouse control thing. Good luck

Hello all. This will probably be my only post as I am rarely on the internet. I wanted to stop by and contribute as I have gained a ton of information from this forum over the past week.

I purchased a used non-running MEP805b unit a couple of weeks ago. It was advertised as needing a mechanical fuel pump. No problem. It arrived, we put one in and it didn’t fire. The power supply light on the ESD5551 “Speed Control Unit” would not light up. This told me the unit was not getting power in or out. The Actuator light would not light at all when turning the engine over. This light should flash for about 3 seconds when starting, even if it doesn’t start. I tested voltage to the ADC100-24 injection pump actuator and it was not getting power. I was able to run 24v from one of the lights on the control panel to the injection pump and it started. You can hear it click when powered. DON’T DO THIS for more than 10 seconds as the speed is not governed. This told me the pump system was fine and it was getting fuel. I was able to trace the issue back to the ESD5551 board. Attached is a photo that shows the two components that were replaced with part numbers. About 70 cents. This restored power to the injection pump and the machine is running now. I still have some tuning work to do but it starts and runs. Parts were purchased from the guys at westfloridacomponents. Other cap suppliers will have the same products. WFC helped us cross reference part numbers making this project possible.

Notes: Try replacing one component at a time. They both may not be bad. Replacing these components should be done by a skilled electronics tech with a good hot air station and solder iron. The silicone epoxy does not melt. It will have to be picked / scraped off. The clear epoxy can be replaced with MG Chemicals 422b compound.

If anyone has dead ESD5551 units laying around I would be interested in them. Please PM me.

Off to solve my dead computer mouse control thing. Good luck

Attachments

-

132.1 KB Views: 79

![IMG_0264[1].JPG IMG_0264[1].JPG](https://www.steelsoldiers.com/data/attachments/655/655139-b247325cc5936638ea7cb32e0d6d5308.jpg)

![IMG_0265[1].JPG IMG_0265[1].JPG](https://www.steelsoldiers.com/data/attachments/655/655140-ee2c2999b75b4d0d7f79d68e77a396b7.jpg)