- 5,637

- 382

- 83

- Location

- Spring Branch, TX

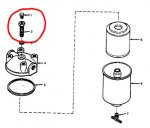

Is there any work around on priming a MEP generator other than the fluid passage bolts on top of the filter canisters? I bought a couple out of Ft Hood and got one running without too much grief but when I went to swap filters on the 2nd I found that they had swapped out the original bolts with regular bolts. I haven't been able to find a source for these on line and need to find some way to bleed the system without them or scrap the unit. While the spin-on option is appealing I'm not really willing to sink that kind of money into it without knowing it'll actually run first.