strosfla

New member

- 54

- 0

- 0

- Location

- Fort Lauderdale, FL

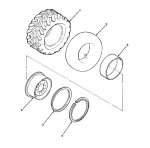

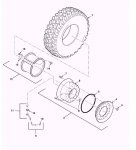

I have (2) new GY 16-20's, and getting a couple new HEMTT rims. I'm pretty good mechanically and have worked in a tire store. My question is : how hard is it to mount up the (2) piece HEMTT 's without special tools. My compressor is 25 gal/125 psi. I've done the starting fluid/torch method on tractor tires so that hazardous maneuver is back there in the mounting portfolio...... so am I in for an azz-kicken or do I just need some will power and elbow grease