In another thread by Tobash,

I posted about running 17" tires on stock HMMWV steel wheels by modifying the rim. It involves removing the bead area on a donor rim and attaching it to the stock steel rims. This is much more complicated than it sounds ... if it sounds easy LOL.

Today I worked on the "Proof of Concept" using a junk rim. I am not welding this on and I will no be using the piece off this rim.

The bead lock rims rely on the inner bead lock pressing the tire into the bead lip on the rim. On the HMMWV rims there is a simple taper where a regular rim has a bead seal. Because of the taper and the design of a regular rim only 1 side of the donor rim has the right dimensions to modify HMMWV stock rim. This means it would will take 10 rims to modify 5 HMMWV rims to fit standard 17" tires.

In the diagram below the BLUE represents the HMMWV Rim.

The GREEN is the Front of the 17" rim I cut off in the following pictures

The RED is the Rear of the 17" rim

The RED/YELLOW is the rest of the 17" rim

The GREEN piece fits perfectly. The lip on the HMMWV would be turned down and welded. It would also be welded where the GREEN and the BLUE meet on the inside at the base of the taper. Keep in mind this is an rough drawing but it's a good representation of the concept.

The RED piece won't work because it doesn't meet the taper. The YELLOW is the gap and could not be welded. It will take another GREEN piece in place of the RED in order to work. So basically it will take two 17" rims to modify 1 HMMWV rim.

View attachment 843835

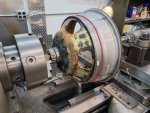

Here is the rim chucked up in the lathe as I cut the front bead section off. Applying cutting oil as it cuts.

View attachment 843836

Here is the donor rim after I cut the bead section off. I'm using 2003-2018 Dodge Dually Wheels for 2 reasons. It's thick and designed for a higher load like the HMMWV wheels. Also it has a 8 x 6.5 bolt pattern and I'm using a HMMWV Spindle in the chuck to mount the wheel.

View attachment 843837

Here is the HMMWV front rim section with the 17" bead section set in place.

View attachment 843838

Here is a close up where the valve goes. The 17" rim will need to be opened up a little to allow the nut to be put on after welding.

View attachment 843839

Here I turned the rim around to plan next cut. In order for it to meet the HMMWV rim it would have to be cut approximately at the red line in the picture. Keeping in mind this is already a heavy wheel it would be adding a lot of extra weight to the already heavy HMMWV wheel. This is the point I decided to stop. I do have another donor rim that I am going to cut the same as this one to continue the proof of concept.

In this picture you get a better shot of the spindle.

View attachment 843841