springer1981

Well-known member

- 861

- 1,184

- 93

- Location

- Maine

I picked up one of the electronic light switches to replace the old style lever switch. The lever switch worked fine and I had complaints about it except the space it took up. The levers stick out and one of the future mods I would like to make is moving the steering column in about 2 inches. This would put the directional lever very close to the light switch levers and likely interfere.

The electronic switch says it is a direct replacement for the mechanical switch however there are tabs that need to be removed from the dash. The tabs are used to space the original switch so that is just stick out of the dash. The new switch is much short and doesn't use the tab. I used a cutoff wheel and made quick work of the tabs.

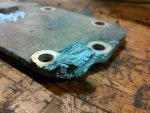

The picture shows the tabs and the red line show where I cut. If I ever wanted to put the original switch back in (4) 3/4" spacers would work to set the correct depth.

I purchased a used steering column on the auction site. I'm going to disassemble it and cut 2 inches out of the shaft and weld it back together. Then I'm going to cut 2 inches out of the housing right in front of the turn signal mount and weld it back together. This will allow me to move the steering wheel about 2 inches closer to the dash giving me a little more breathing room.

I installed the later style A2 steering wheel. It is a little thicker and has a slightly better feel to it. It is still just a hard plastic wheel and doesn't offer much grip. If the steering column mod works out I will wrap the new wheel with either a vulcanizing rubber or leather to add a little grip and cushion.

While investigating modifying the steering column I closely checked out all the steering column mounts to see if there is any other way than actually cutting it down. There really isn't an alternative option but I did see a curved slot on both side mount. After checking it out I realized the steering column can be raised and lowered giving it a "tilt" option.

How to-

There is a bolt under the steering column that clamps the mounting bracket around the column. It's in plain site as soon as you look under the steering column.

There are also 2 bolts at the bottom of steering column, 1 on each side.

Loosen those 3 bolts and you should be able to move the steering column up and down about 3" of travel. Pick the spot you like the most and tighten the 3 bolts.

The electronic switch says it is a direct replacement for the mechanical switch however there are tabs that need to be removed from the dash. The tabs are used to space the original switch so that is just stick out of the dash. The new switch is much short and doesn't use the tab. I used a cutoff wheel and made quick work of the tabs.

The picture shows the tabs and the red line show where I cut. If I ever wanted to put the original switch back in (4) 3/4" spacers would work to set the correct depth.

I purchased a used steering column on the auction site. I'm going to disassemble it and cut 2 inches out of the shaft and weld it back together. Then I'm going to cut 2 inches out of the housing right in front of the turn signal mount and weld it back together. This will allow me to move the steering wheel about 2 inches closer to the dash giving me a little more breathing room.

I installed the later style A2 steering wheel. It is a little thicker and has a slightly better feel to it. It is still just a hard plastic wheel and doesn't offer much grip. If the steering column mod works out I will wrap the new wheel with either a vulcanizing rubber or leather to add a little grip and cushion.

While investigating modifying the steering column I closely checked out all the steering column mounts to see if there is any other way than actually cutting it down. There really isn't an alternative option but I did see a curved slot on both side mount. After checking it out I realized the steering column can be raised and lowered giving it a "tilt" option.

How to-

There is a bolt under the steering column that clamps the mounting bracket around the column. It's in plain site as soon as you look under the steering column.

There are also 2 bolts at the bottom of steering column, 1 on each side.

Loosen those 3 bolts and you should be able to move the steering column up and down about 3" of travel. Pick the spot you like the most and tighten the 3 bolts.