als804

Member

- 89

- 66

- 18

- Location

- kimcheon, ROK

Exhaust Pipe

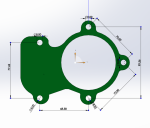

chinese copy hx35w turbine outlet flange has 2.5inch so i had to make my own flange for 3inch down pipe. u can use but bolt holes need more bigger bored. i used 3 inch 304 Stainless pipe of Downpipe. and there is no space at where stock-down pipe goes down due to Crossover pipe so i had to cut the covers with plasma cutter

initially i used direct 3 inch pipe but it seriously louds i can't do windows down due to noise. at Rpm range more than about 2400rpm the engine screams severely so i installed The Resonator at the End of downpipe. it made it quieter a lot. and still quick spool and intake whistle sounds a lot

chinese copy hx35w turbine outlet flange has 2.5inch so i had to make my own flange for 3inch down pipe. u can use but bolt holes need more bigger bored. i used 3 inch 304 Stainless pipe of Downpipe. and there is no space at where stock-down pipe goes down due to Crossover pipe so i had to cut the covers with plasma cutter

initially i used direct 3 inch pipe but it seriously louds i can't do windows down due to noise. at Rpm range more than about 2400rpm the engine screams severely so i installed The Resonator at the End of downpipe. it made it quieter a lot. and still quick spool and intake whistle sounds a lot

Attachments

-

413.2 KB Views: 4