goldneagle

Well-known member

- 4,737

- 1,508

- 113

- Location

- Slidell, LA

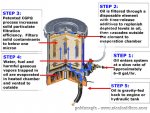

I have been reading a lot of the posts about Oil filter modifications, relocations and pre-lube. While searching on Ebay I ran across a Bypass Oil Filter Kit that I think the members would jump at... I contacted the seller and he told me he has at least 80 of these units available. They run 12/24 volts.

Here are some specs on the Filter System:

Puradyn PF-12 20 qt. Bypass Oil Filter KIt

Here is a link to the Puradyn Web Site:

http://www.puradyn.com/products/elements.html

You can get them for $110 shipped if you ask the seller nicely..

Feel free to contact me and I will give you his contact info...

I want to thank everyone that posted all the info on oil filter changes and mods. It was very educatioal!!

Here are some specs on the Filter System:

Puradyn PF-12 20 qt. Bypass Oil Filter KIt

Here is a link to the Puradyn Web Site:

http://www.puradyn.com/products/elements.html

You can get them for $110 shipped if you ask the seller nicely..

Feel free to contact me and I will give you his contact info...

I want to thank everyone that posted all the info on oil filter changes and mods. It was very educatioal!!