BrassBuilder

Member

- 30

- 0

- 6

- Location

- Mitchell, SD

Hey all,

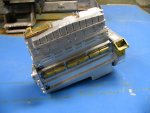

Been a lurker here for awhile. I stop in once every couple of weeks. I'm building a 1/8 scale M915A1 and thought I'd post some pics of what I have done so far. This is just going to be a few random shots without a lot of indepth explaining. I'm also posting more pics on my website at www.firesteelhobbies.com.

I'll see about posting more updates here.

Mike

Been a lurker here for awhile. I stop in once every couple of weeks. I'm building a 1/8 scale M915A1 and thought I'd post some pics of what I have done so far. This is just going to be a few random shots without a lot of indepth explaining. I'm also posting more pics on my website at www.firesteelhobbies.com.

I'll see about posting more updates here.

Mike

Attachments

-

48.4 KB Views: 229

-

81.6 KB Views: 227

-

46 KB Views: 208

-

55 KB Views: 223

-

52.3 KB Views: 208

-

41.7 KB Views: 214

-

48.6 KB Views: 279

-

43.5 KB Views: 237

-

61.6 KB Views: 261

-

42.1 KB Views: 223