BINGO !! What did it win? Not another toaster lol.

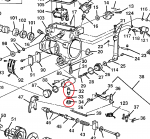

Sleep or study up on the DB2 metering valve. It's a little fuel control valve down in the bottom center rear (from front of truck) of the reservoir that needs to move freely. Looks like a little wing flipper thingie with linkage. If sticky / sluggish action it MAYBE gummed up.

Since you have the housing cover off, check for play ... flip flop like in the movie. ( I don't endorse statements, just the visual to locate it and action) Pictures worth a thousands words haha. SEE >

Funny statement at end "that what you want to do" LOL

One can refill / top off reservoir, CAREFULLY and proper reassemble cover / wires. Attempt to give it a few tries to start. This may not be the fix or a permanent solution. As I said "a free guess" to get fuel flowing if it is all gummed up.

There's a LOT going on in the DB2 IP and not enough bandwidth here. Save up some $$$ if one need a pump.

Wasn't BINGO a dog? CAMO