- 8,229

- 20,779

- 113

- Location

- Charlotte NC

.from previous discussions..... based on location of the oil pressure switch...... by the time that switch reads low oil pressure..... your engine is already toast. Oil line of death just pumps the oil out way to fast.

Issue also is....... automatic shut off...... while saves your engine..... it likely kills person(s) on the highway behind you as your truck suddenly out of the blue in the middle lane loses all power, resulting in cars, trucks behind you eating your ass in a pile up. Driver of FMTV does not want to brake (so no brake lights show), they want/need power to safely steer it off the road but can't cause engine was auto shut down.... that is a lose lose situation.

So comes down too.... save your engine vs pile up accidents behind you that kills one or more.

Well thanks. At least that is a reasonable "why" for how it is coachgeo .

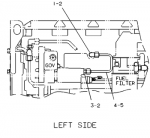

Wonder if there is a better place for a low oil switch?

Cynicism On -

Maybe what we do is attach an air horn on the inside back wall of the cab.

Then, when the massive oil loss situation happens, the driver will have a heart attack and never know that his motor was blown.

Cynicism Off -

On a more positive note, Regularly checking bolts and looking / feeling weird vibrations are something that CAN be overcome. Especially if you know that it is a concern. These trucks, most diesel truck in general shake themselves to death before they actually wear out.