Another Ahab

Well-known member

- 18,140

- 4,942

- 113

- Location

- Alexandria, VA

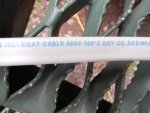

What are you figuring for the inside sheathing:Whew. Tired, but got a fair amount done this weekend. Installed 4 outside outlets, two shown, got about 98% of my 110v ac wiring in, and about 75% of my 12v dc wiring done. Still need to install and wire the 12v fuse box. Breaker panel mostly wired. Need to instal the wall board, ceiling boards and the bathroom walls before much else wiring wise can be completed.

- Regular sheetrock (3/8")?

- Moisture-resistant board?