- 2,113

- 563

- 113

- Location

- Davis County, UT

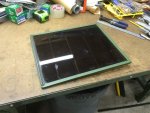

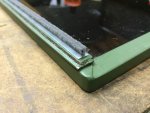

Be very careful with the insulation. It'll even stick to the back side of its own backing plastic and will only tear itself coming off (you know, if while peeling it off, the backing plastic gets folded back on itself).

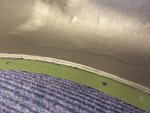

I just screwed up big like a moron. I should have cut it out in straight lines before I tore off the looser chunks.

At this point, you're not getting anything off unless you scrape off the entire sound deadening too (what a mess that'd be).

So I just adhered another layer of insulation and I can see my shame forever. I actually wanted two layers of insulation on the top anyway, I think I'll put a third here so it's less visible.

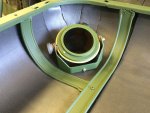

At least the corners came out awesome (which will be covered by lights of course).

I just screwed up big like a moron. I should have cut it out in straight lines before I tore off the looser chunks.

At this point, you're not getting anything off unless you scrape off the entire sound deadening too (what a mess that'd be).

So I just adhered another layer of insulation and I can see my shame forever. I actually wanted two layers of insulation on the top anyway, I think I'll put a third here so it's less visible.

At least the corners came out awesome (which will be covered by lights of course).

Last edited: