- 2,827

- 3,923

- 113

- Location

- Montgomery, Texas

It took a lot longer than expected (axles & breaks)

I drove my truck this weekend... For the first time since the 2015 Texas Rally last March!!!!

This weekend also marks the completion of work on all three axles and the brake system. My truck has been inoperable for the last six months partly because I kept finding issues to repair and partly because I have been insanely busy at work leaving little time for hobbies. I truly enjoy working on my truck and the learning that comes with experience. But, I am a little ticked-off because I paid a premium for this truck two years ago from a company in Southern California that supposedly "rebuilt" the truck. I know understand that their version of "rebuild" means they changed fluids and painted over years of dirt and grease (yes, they actually painted over the dirt and grease).

My takeaway from all of this is... Regardless of whom you buy a 40-year old truck from and regardless of what they tell you, inspect it and know for certain what you have! Don't take someone else's word for it. If you lack experience (like I do), find someone knowledgeable and trustworthy to inspect the truck for you. Be there for the inspection and ask a lot of questions! Now, I am very lucky to know a good mobile mechanic with decades of experience that comes out to help on my truck.

Here is the mobile mechanic and my "storage unit" shop:

I'm very lucky that the storage facility lets me work on my truck in the storage unit!

Here's a summary of the work that we finally completed this weekend:

Wheel Cylinders & Front Axle Boots - The front left wheel cylinder went-out last year. No big deal! My mobile mechanic buddy came-up and got it squared away in no time flat. He told me that when one goes, the rest usually follow in short order. At that time (in 2014), I began planning to replace the remaining 5 wheel cylinders. I also needed to replace the front axle boots (apparently they were not included in the "rebuild" I paid for). Here are some pictures of the old boots and Southern California sand that came in the axle of my "rebuilt" truck:

I did a lot of reading on this website and then acquired all of the parts, which included one of Rockwelloffroad.com's front axle kits (boots and seals) that I purchased second hand from another SS member. (Note that Rock6x6 is a vendor on this site and sells their products through Rockwelloffroad.com. More about them below.)

Early in 2015, I lost a wheel cylinder on the center axle. In March 2015, I took a little time off from work, and the mechanic came back. We planned to replace the remaining 5 wheel cylinders and the front axle boots. The plan was to complete all of this work before the 2015 Texas Rally. We were only able to get the rear axles done before running out of time. That was good enough to get me to the rally and made for a great weekend!

However, shortly after the rally, the last unchanged wheel cylinder on my truck (front right) went out in early April. Then a couple projects came-up at work and a few months past in the blink of an eye! It was late August 2015 before I was able to return to my truck. Now with all the parts still in hand, all we had to do was tear-down the front axle and rebuild with new seals, boots and a wheel cylinder. No big deal... right? We started the work on a Friday (a rainy Friday). This is us "playing" in the rain:

Everything was going very smooth until one of the brand new axle boots tore in my hand! Despite this, I still have favorable comments about Rockwelloffroad.com. I called their shop late that Friday afternoon. Fortunately, they are not too far from my home (only a 3 hour drive). The gentleman that answered the phone was very friendly and very helpful. I explained my dilemma, and he offered to meet me at a gas station out on the highway as soon as I could get there (i.e., late evening on a Friday). I was extremely impressed by their customer service! That gentleman went way over and above what I would expect from a parts shop! Now here's the kicker... He explained to me that their early axle boot design was flawed (this was the one that ripped in my hand). They now have a new design that is much thicker and easier to install. If you purchased an axle boot from them before 2015, try and get a replacement or just throw it in the trash. Their old design is not worth messing with (in my opinion). I had no recourse against Rockwelloffroad.com since I purchased the kit second hand from another SS member. I was just very happy to get a good boot so I could continue work that weekend.

I purchased new axle boots from them that Friday evening and my mechanic buddy came back the next day so we could finish (at least I thought...). That Saturday morning, while putting everything back together, we noticed my brake lines were in dangerously bad condition. We got the axle put back together, and then I ordered a new set of lines from Peashooter. I also built a power bleeder using Recovry4x4's design. Here are the old break lines, new break lines and power bleeder:

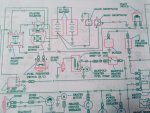

Fast forward a couple of weeks, the brake lines came in the mail and my mechanic buddy came back to lend a hand again. Installing the brake lines was quick and easy. Using the pressure bleeder, we pressured-up the brake system and went to bleed the air pack. Right then the front boot on the master cylinder gave out and shot brake fluid everywhere! Worked stopped that day, and I ordered a new master cylinder from Clintogf. For good measures, I also ordered a NOS air pack from White Owl.

Again, fast forward a couple of weeks to this weekend. Between the two of us (my mechanic and I), replacing the master cylinder, replacing the air pack and bleeding the brake system was a pretty quick job. This time everything worked!!! It was great to finally drive my truck again this weekend!!

Here is a very old air pack. Although it hadn't gone out yet, I knew it was just a matter of time:

So is there an SS award for taking the longest to fix something?????

I drove my truck this weekend... For the first time since the 2015 Texas Rally last March!!!!

This weekend also marks the completion of work on all three axles and the brake system. My truck has been inoperable for the last six months partly because I kept finding issues to repair and partly because I have been insanely busy at work leaving little time for hobbies. I truly enjoy working on my truck and the learning that comes with experience. But, I am a little ticked-off because I paid a premium for this truck two years ago from a company in Southern California that supposedly "rebuilt" the truck. I know understand that their version of "rebuild" means they changed fluids and painted over years of dirt and grease (yes, they actually painted over the dirt and grease).

My takeaway from all of this is... Regardless of whom you buy a 40-year old truck from and regardless of what they tell you, inspect it and know for certain what you have! Don't take someone else's word for it. If you lack experience (like I do), find someone knowledgeable and trustworthy to inspect the truck for you. Be there for the inspection and ask a lot of questions! Now, I am very lucky to know a good mobile mechanic with decades of experience that comes out to help on my truck.

Here is the mobile mechanic and my "storage unit" shop:

I'm very lucky that the storage facility lets me work on my truck in the storage unit!

Here's a summary of the work that we finally completed this weekend:

Wheel Cylinders & Front Axle Boots - The front left wheel cylinder went-out last year. No big deal! My mobile mechanic buddy came-up and got it squared away in no time flat. He told me that when one goes, the rest usually follow in short order. At that time (in 2014), I began planning to replace the remaining 5 wheel cylinders. I also needed to replace the front axle boots (apparently they were not included in the "rebuild" I paid for). Here are some pictures of the old boots and Southern California sand that came in the axle of my "rebuilt" truck:

I did a lot of reading on this website and then acquired all of the parts, which included one of Rockwelloffroad.com's front axle kits (boots and seals) that I purchased second hand from another SS member. (Note that Rock6x6 is a vendor on this site and sells their products through Rockwelloffroad.com. More about them below.)

Early in 2015, I lost a wheel cylinder on the center axle. In March 2015, I took a little time off from work, and the mechanic came back. We planned to replace the remaining 5 wheel cylinders and the front axle boots. The plan was to complete all of this work before the 2015 Texas Rally. We were only able to get the rear axles done before running out of time. That was good enough to get me to the rally and made for a great weekend!

However, shortly after the rally, the last unchanged wheel cylinder on my truck (front right) went out in early April. Then a couple projects came-up at work and a few months past in the blink of an eye! It was late August 2015 before I was able to return to my truck. Now with all the parts still in hand, all we had to do was tear-down the front axle and rebuild with new seals, boots and a wheel cylinder. No big deal... right? We started the work on a Friday (a rainy Friday). This is us "playing" in the rain:

Everything was going very smooth until one of the brand new axle boots tore in my hand! Despite this, I still have favorable comments about Rockwelloffroad.com. I called their shop late that Friday afternoon. Fortunately, they are not too far from my home (only a 3 hour drive). The gentleman that answered the phone was very friendly and very helpful. I explained my dilemma, and he offered to meet me at a gas station out on the highway as soon as I could get there (i.e., late evening on a Friday). I was extremely impressed by their customer service! That gentleman went way over and above what I would expect from a parts shop! Now here's the kicker... He explained to me that their early axle boot design was flawed (this was the one that ripped in my hand). They now have a new design that is much thicker and easier to install. If you purchased an axle boot from them before 2015, try and get a replacement or just throw it in the trash. Their old design is not worth messing with (in my opinion). I had no recourse against Rockwelloffroad.com since I purchased the kit second hand from another SS member. I was just very happy to get a good boot so I could continue work that weekend.

I purchased new axle boots from them that Friday evening and my mechanic buddy came back the next day so we could finish (at least I thought...). That Saturday morning, while putting everything back together, we noticed my brake lines were in dangerously bad condition. We got the axle put back together, and then I ordered a new set of lines from Peashooter. I also built a power bleeder using Recovry4x4's design. Here are the old break lines, new break lines and power bleeder:

Fast forward a couple of weeks, the brake lines came in the mail and my mechanic buddy came back to lend a hand again. Installing the brake lines was quick and easy. Using the pressure bleeder, we pressured-up the brake system and went to bleed the air pack. Right then the front boot on the master cylinder gave out and shot brake fluid everywhere! Worked stopped that day, and I ordered a new master cylinder from Clintogf. For good measures, I also ordered a NOS air pack from White Owl.

Again, fast forward a couple of weeks to this weekend. Between the two of us (my mechanic and I), replacing the master cylinder, replacing the air pack and bleeding the brake system was a pretty quick job. This time everything worked!!! It was great to finally drive my truck again this weekend!!

Here is a very old air pack. Although it hadn't gone out yet, I knew it was just a matter of time:

So is there an SS award for taking the longest to fix something?????

![$(KGrHqR,!i4E7FuP+jt3BO7d0)dR3g~~60_57[1].jpg $(KGrHqR,!i4E7FuP+jt3BO7d0)dR3g~~60_57[1].jpg](https://www.steelsoldiers.com/data/attachments/400/400530-782dfd70ec27114f8171e22a168e5561.jpg)