Well it could be that the washers you received where sub par. I got some with one or two of the wheel cylinders when I replaced all of mine. Also did you torque the banjo bolt to the spec of 65 lb-ft. I thought I was going to bust the darn thing but it didn't.

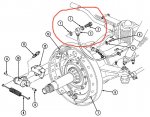

"4. Install hose connector (3) to wheel cylinder (10) with two washers (1) and brake line screw (2).

Tighten screw (2) 65 lb-ft (88 NŽm)."

I found this very helpful, thank you.

I wanted to know where this was. While many, many TMs are available here on Steel Soldiers, they are

completely lacking in organization and it's difficult to know which ones will have what you need. Some of the TM titles are helpful and you know you can skip the "Multifuel" ones when you're after something in the axle, but many of the TM titles contain no help as to what it actually covers. So I went digging and generally have to resort to opening several to find out they don't cover what I'm after.

If anyone is interested in where this figure and instructions is located in the "

Technical Manuals" -> "

The Deuce TMs" forum -> "

TMs for the Deuce" thread

TM9-2320-361-20.pdf

TM9-2320-361-20 Technical Manual and Unit Maintenance. (Later Edition TM)

Section 8-9 Hydraulic Wheel Cylinder Replacement, pg. 8-24

PDF Page 598 of 1209