helomedic1171

Member

- 205

- 13

- 18

- Location

- Dacula, GA

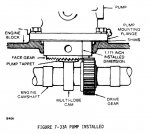

Some of you may remember the MEP-003 I picked up a couple of months ago, which was missing just about everything. I've since got the parts I need, and started putting everything together. I tried to crank it tonight, and it turns over, but will not start/run. The genset didn't have an IP on it at all, and I suspect the timing is where the malfunction is. how do I reset the pump timing? with no pump to go by, I'm not even at square one, I'm farther behind.

I changed all the filters with new ones, used fresh JP-8, both main pumps are clicking away, there's fresh oil and a new oil filter, I'm at a loss.

I changed all the filters with new ones, used fresh JP-8, both main pumps are clicking away, there's fresh oil and a new oil filter, I'm at a loss.