- 1,308

- 1,679

- 113

- Location

- Basehor, KS

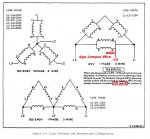

Wiring Diagram for the correct Hammond PH250MGJ as T2 replacement in A11

Ok folks,

here it is.

Math:

Original T2 Transfer Ratio:

208VAC to 128VAC = 1.625 : 1

Hammond PH250MGJ Tansfer Ratio:

387VAC to 240VAC = 1.6125 : 1

Maximum Output Current on Secondary side in this configuration: 1.04 Amps AC (twice of whats needed)

Note: a transformer does not care if you apply a lower Voltage on the primary, you will get exactly the transfer ratio on the output up to max current of the secondary - because this a CE rated transformer it is 387 instead of 380 even though it says it on the label.

And the PDF to download

Ok folks,

here it is.

Math:

Original T2 Transfer Ratio:

208VAC to 128VAC = 1.625 : 1

Hammond PH250MGJ Tansfer Ratio:

387VAC to 240VAC = 1.6125 : 1

Maximum Output Current on Secondary side in this configuration: 1.04 Amps AC (twice of whats needed)

Note: a transformer does not care if you apply a lower Voltage on the primary, you will get exactly the transfer ratio on the output up to max current of the secondary - because this a CE rated transformer it is 387 instead of 380 even though it says it on the label.

And the PDF to download

Attachments

-

226.2 KB Views: 4

Last edited: