That datasheet is for the high-frequency (30-60kHz) version, this is the one I have....I attached the Datasheet

Thanks

Attachments

-

293.4 KB Views: 5

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

That datasheet is for the high-frequency (30-60kHz) version, this is the one I have....I attached the Datasheet

Thank you Marcel,Peter,

No rush at all - I'm just grateful for yours and Kurt's support. I've gone ahead and ordered a NOS IGBT module just in case. I figure while I'm in here I might as well replace anything which appears suspect (or could be), and hope for the best.

I kind of regret having sourced the slightly shorter (40mm) caps as opposed to the full-height (45mm) version, as the ripple-current is slightly better. Problem was, I didn't find any in stock. Having said that - my MEP-831a saw 1300 or so hours in combat with the USMC before this happened, so I doubt I'll be replacing them again...if so, I'll be an expert!

Thanks again!

-Marcel

Marcel,That datasheet is for the high-frequency (30-60kHz) version, this is the one I have.

Thanks

Marcel,Peter, I like it although I wouldn't know where to start to implement it!

Sticking to the basics, I've sourced a sh*tload of Vishay S103K75Y5PN65K0R caps to replace the Hitano garbage as I pick through the rebuild. I also ordered replacement Vishay 600V 15A Hyperfast FREDs just in case the originals were damaged..

If after all this, the thing goes up in smoke again...at least the baby carp in Lake Norman will have some shiny objects to look at in their underwater museum.

I will see whether I can change the FRED order to the 30A version (VS-E5PX3006L-N3). They are a bit slower, but not by much.On the hyperfast freds you can also go with a higher current rating then 15 Amps. It may cost a few bucks more for the whole batch but the higher the current rating the less stress the diode experiences during communication

Peter

Marcel,

The Fred’s and similar devices were designed for fast switching power supplies and the 60Hz they have to contend with here is more like molasses in comparison.I will see whether I can change the FRED order to the 30A version (VS-E5PX3006L-N3). They are a bit slower, but not by much.

Thanks!

Marcel,THE STRIPPER IS ON THE WAY!

I thought I'd make my morning post sound like fun...speaking of which - I'd had more fun in H.S. detention!

View attachment 876753

Those electrolytics were a PITA to pull. I think I'll wait for the stripper to arrive before I attack the diodes and ceramic caps...I am still trying to catch the order to upgrade the diodes to 30A before they ship.

That's all for today.

Thanks Peter!great job! When you strip the board, check the 4 resistors

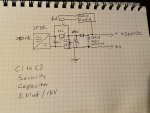

Peter, no ESR tester - just a crappy Chinese knock-off capacitor tester with a yellow case made to look like a Fluke...Do you have a ESR tester?

Thanks Peter!

I think I'd make the resistor bands to be blue, green, orange, and gold. Green could be brown, but I doubt it...In any event, I'll verify once pulled from circuit mid-week when other parts arrive,

I've ordered the caps and diodes from Arrow Electronics, which is my primary source for electrical components. I believe them to be reputable (despite them being a "global" corp).

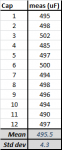

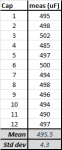

View attachment 876835

Peter, no ESR tester - just a crappy Chinese knock-off capacitor tester with a yellow case made to look like a Fluke...

...assuming the tester tells the complete story, no smoking gun here as the caps all test well within their +/- 20% spec (worst-case within 3%)...

Thanks,

Marcel

Marcel,Thanks Peter!

I think I'd make the resistor bands to be blue, green, orange, and gold. Green could be brown, but I doubt it...In any event, I'll verify once pulled from circuit mid-week when other parts arrive,

I've ordered the caps and diodes from Arrow Electronics, which is my primary source for electrical components. I believe them to be reputable (despite them being a "global" corp).

View attachment 876835

Peter, no ESR tester - just a crappy Chinese knock-off capacitor tester with a yellow case made to look like a Fluke...

...assuming the tester tells the complete story, no smoking gun here as the caps all test well within their +/- 20% spec (worst-case within 3%)...

View attachment 876834

Thanks,

Marcel

Silly me! When I started measuring them and they all came in around 500 I completely forgot they were supposed to be 560uF and not 500. To be consistently off by on average 12% is in itself interesting. Maybe a dry 560 becomes a 500 - in which case they even fail the same way???...These are 560uF caps

Marcel,Silly me! When I started measuring them and they all came in around 500 I completely forgot they were supposed to be 560uF and not 500. To be consistently off by on average 12% is in itself interesting. Maybe a dry 560 becomes a 500 - in which case they even fail the same way???

I will measure the resistors as I pull them and will replace with a suitable quality part.

thanks,

Marcel

The range goes up to 20mF.What is upper capacitance value your tester can test to?

Is this 20 mili (e-3) Farad or 20 mikro (e-6) Farad? The Chinese are not used to our numerical system.The range goes up to 20mF.

I've been scouring the internet for 65k 2w ceramic resistors, and they appear to be unicorns. How critical would the value be (62k and 68k readily available)?

20 mili...it goes from 2000 pF-->2 uF-->20 mF in ten steps.Is this 20 mili (e-3) Farad or 20 mikro (e-6) Farad? The Chinese are not used to our numerical system.

Done it. I wasn't able to change my order to the 30A FREDs since Arrow mysteriously sold out overnight, so I ordered them thru mouser along with the metal film resistors. I'll just return the 15A FREDs after they arrive.As to resistor, use this one here: