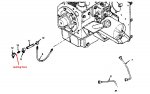

Leak fixed. After removing Items 10-12 in the below diagram, I inspected and cleaned them once again; check valve did not have any debris in or around it and the internal valve moved freely and was not "sticky". I then reinstalled everything to test pressure of the fuel system; I first tested at the upstream hose fitting coming out of the last fuel filter; the pressure held at 10+ PSI for 5 mins with no leaks downstream. I then tested at the 90° fitting (#10 of the diagram) upstream from the Check Valve; the pressure held at 10+ PSI for 5 mins with no leaks downstream. I then reconnected everything turned S1 to Prime for 5+ minutes and no leaks...there was a small amount for fuel going into the day tank via the IP return hose as it should be.

View attachment 939097

I then tried to start it. It fired up, came up to speed and ran for about 2 mins then the same issue; RPM's would slowly decrease to where it would start knocking then it would recover, back up to speed, then slowly decrease RPM, knock with gray/white smoke...Just a FYI, I'm not letting it continually run this way or till it dies for fear of damaging any of the electronics, I just shut it off.

I was very comfortable and confident working on the Fuel System but now I am so frustrated because I don't know enough about this machine to properly diagnoses what's going on with it and feel I don't always have the best ability to describe it to you guys in a way that you can help...Ah, it's so frustrating....

Below are a few Videos of what it's doing and what the Governor linkage is doing...if it helps?

Vid-A

Vid-B

Vid-C

View attachment 939104 View attachment 939103 View attachment 939102

Thanks All!!!!