Just saw you had replied, already finished one seal tool. Ran it through Ansys and webbing/relieved design was about 70% weaker in a failure analysis than simple flare. Having been deeply involved in CAD/CAM for some time now I can lend a hand in durable and cost effective FDM/SLA modeling.

Have to be careful with that thinking. There is always "better", but the real trick is knowing what is "good enough". The long taper on the flare is mostly for printability, it didn't need it for strength. So the cuts were to remove material that did not need to be there, and were just raising print time and material cost. So it's 70% weaker, in a place that was already 100%+ too strong to begin with, which actually means it can be cut away further! That flare cone is not where it fails - it fails around the thin driving lip, which really can't be changed because it has to fit the seal.

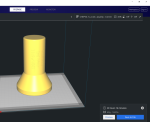

I made a reinforced version (bolstered shaft diameter and longer taper from head end), printed in FDM at 45% infill (triangle pattern) it will survive quite a while. I always add more shell layers for parts that need to be durable as well as raising the temp some.

This is a waste, with additive manufacted designs. There is no need for the volume, so increasing the volume just to shell it and hollow with infill, is typically counterproductive. (There are some cases where you need to create a thicker but hollower part, such as to spread layer adhesion, or a stressed-skin structure.) Thin it down, and just print it solid (90% infill). All that extra infill just results in longer cycle times on the toolpaths, where the simple perimeters would have been both faster and stronger. Also, for a seal driver, you want it to be as solid as possible, so that it is transmitting as much driving force to the part, instead of absorbing it internally with an infill grid.

In SLA (resin) it will be equally as durable with a 50/50 blend of Siraya Blu and Siraya Tenacious, with the added benefit of printing faster and having much more precision. I started years ago in FDM and jumped into SLA as soon as it became available due to the consistent results and level of detail provided.

I disagree with this. SLA printing is just the "wrong tool for the job", as it focuses more on precision with less impact resistant materials. FDM is able to adequately meet the precision needs, with materials that have better mechanical properties. I was curious, and printed two in SLA, with the mid-grade "ABS-like" resins (which is not an accurate description)... one chipped around the edges, making it poor for driving the seal nicely, and the other one I crushed in the press (not an ideal test, but I was mostly just double-dipping, screwing around with new resins, and new part designs).

Printed in FDM (plastic): Approximately 23 hours, with a material usage of 341 grams (about $8.00 dollars in PLA+).

Printed in SLA (Premium durable resin): 9 hours, with a material usage of 540 grams (about $23.00 dollars in Siraya blend).

* Of note: If I select a normal resin, the price drops to approximately 10 dollars, however longevity will suffer.

PLA isn't a good choice for functional parts, especially things like this that really need the impact resistance. ABS, ASA, or Nylon would be good, but add printing complications (e.g. heated build chamber, warping, weaker layer adhesion, etc.). PETG is a pretty good compromise.

My design for the same seal driver, printed solid (90%) is 360g. Print time 20h.

It's worth pointing out to others who might read this, he's just quoting material cost, not shop time (e.g. material cost + electricity + wear/repairs on the lifespan of the machine + labor +...).

I had considered a couple other options for the design, such as using a piece of metal pipe or conduit, with just 3D printed caps for the ends. I decided that I didn't want to mess with that, and that people probably wouldn't want to have to get a big piece of pipe just to cut out the 5" section they need, so it was better to print the whole thing. Gotta keep that part count down, anyway.