devilman96

New member

- 2,056

- 17

- 0

- Location

- Boca Raton, FL

A little bit of an update...

Since I am waiting on sheet metal to paint and everything to proceed that I am trying to stay busy but not get to far ahead of myself.

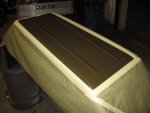

I have started on some of the paint, mostly the inside stuff or I have just accepted having to paint some things twice but I am getting the hard parts out of the way with seam sealing and aluminum oxide on the walk ways of the fenders, etc. The hood is painted and undercoated on the bottom so I will spare masking later. I could not decide on the "warning, don't leave the hood flopping around to all on your head" thingo... My hood had it on both top and bottom so I masked it to go back on the bottom side??? Correct or not at least I will get the lettering back on...

Lots of wiring stuff... I made a panel for under the dash which will run all of my 12/24V functions as seamlessly as possible. In short I am using 12 and 24 volt relays to control all of my accessories based on the ignition switch's position as you would expect a "normal" truck to work... IE "run" turns everything on (radios, window motors, seats, etc) start allows nothing to be on, and the accessory position to allow just the radios to function. I am working on redundancy with this and though it looks complicated and will be a "busy" with wires I can yank the whole panel and the truck still starts, runs and drives as it should with its 24V system so if anything fails or craps out for any reason I still have a functional vehicle. It is also designed to be fixed roadside, all labeled correctly and all common parts so a few spare fuses and a 24 and 12 volt relay would allow you to repair anything on the fly. It is also modular... If I need to completely redesign it later or make changes all I have to do is disconnect 7 wires and its out of the truck....

I am also updating the plug ends on the whole truck to the newer "weather tight" fittings found on most cars and equipment... It might not be military but I think in the long haul these will be much easier to deal with when pulling parts or trouble shooting / testing the system while still retaining water tight plugs.

I am also getting the time to pick up some odds and ends that will make the truck more drivable... I am going with electric window wipers from a CJ jeep (easy /cheap kit to find and work with)... electric windshield washer unit, remote brake reservoir for the firewall and a over flow reservoir for the radiator... If I can figure out where in the hell to mount all of this stuff... and HOPEFULLY its Orlando this weekend and paint next week...

Since I am waiting on sheet metal to paint and everything to proceed that I am trying to stay busy but not get to far ahead of myself.

I have started on some of the paint, mostly the inside stuff or I have just accepted having to paint some things twice but I am getting the hard parts out of the way with seam sealing and aluminum oxide on the walk ways of the fenders, etc. The hood is painted and undercoated on the bottom so I will spare masking later. I could not decide on the "warning, don't leave the hood flopping around to all on your head" thingo... My hood had it on both top and bottom so I masked it to go back on the bottom side??? Correct or not at least I will get the lettering back on...

Lots of wiring stuff... I made a panel for under the dash which will run all of my 12/24V functions as seamlessly as possible. In short I am using 12 and 24 volt relays to control all of my accessories based on the ignition switch's position as you would expect a "normal" truck to work... IE "run" turns everything on (radios, window motors, seats, etc) start allows nothing to be on, and the accessory position to allow just the radios to function. I am working on redundancy with this and though it looks complicated and will be a "busy" with wires I can yank the whole panel and the truck still starts, runs and drives as it should with its 24V system so if anything fails or craps out for any reason I still have a functional vehicle. It is also designed to be fixed roadside, all labeled correctly and all common parts so a few spare fuses and a 24 and 12 volt relay would allow you to repair anything on the fly. It is also modular... If I need to completely redesign it later or make changes all I have to do is disconnect 7 wires and its out of the truck....

I am also updating the plug ends on the whole truck to the newer "weather tight" fittings found on most cars and equipment... It might not be military but I think in the long haul these will be much easier to deal with when pulling parts or trouble shooting / testing the system while still retaining water tight plugs.

I am also getting the time to pick up some odds and ends that will make the truck more drivable... I am going with electric window wipers from a CJ jeep (easy /cheap kit to find and work with)... electric windshield washer unit, remote brake reservoir for the firewall and a over flow reservoir for the radiator... If I can figure out where in the hell to mount all of this stuff... and HOPEFULLY its Orlando this weekend and paint next week...

Attachments

-

34.1 KB Views: 2,624

-

24.7 KB Views: 2,580

-

29.2 KB Views: 2,595

-

28.2 KB Views: 2,584

-

63.5 KB Views: 2,597

-

55.5 KB Views: 2,569