- 3,657

- 29

- 48

- Location

- Dallas, Texas

Please help me out here from your vast knowledge of heavy duty trucks and equipment!

Well Santa bit the bullet and bought me a diesel genset. This is the smallest one of apparently good quality that he could find. Unfortunately, his note said that even though I had been very good, I'd have to mount it myself!

(the DC power packs at Shirley's seem too wide/long to fit on the truck since the bed is full, does anyone have the TM or dimensions for reference?).

The salesman let me have it for 40% off list ($309 since I explained it's honestly for use in emergency communications.

since I explained it's honestly for use in emergency communications.

The most desirable goal is to mount it in place of the pioneer tool kit. The overall dimensions suggest removal of the spare tire winch and mount, but the close fit remains to be seen. If the spare goes, then the truck will most likely (prudently) stay a 10-wheeler instead of being singled with taller tires.

The set chosen was the GPNDL-60E from Gillette Generators

http://www.gillettegenerators.com/portable/specs04x.html

which is a 5KW continuous duty (prime, 6KW max.) diesel set. This is enough for powering the S-280 shelter with air conditioning.

Dimensions are 28Lx23Hx20W and mass is 207 Lbs. There was a model GPNDL-40E (4KW/3.5KW prime) which was smaller but is it discontinued due to less demand.

These have Lombardini engines, much better than the Chinese models, having researched and found complaints and parts issues. I have been very afraid of the chinese diesels. Gillette apparently makes the alternators and then integrates the engine and other items into a package.

The genset is 2" longer than the space between the mud flap and the front of the bed. It looks like the best mounting will require me to remove the front brace of the bed corner, that is the large triangular piece at the front of the bed. I don't want to do that but forsee any problems to be caused by doing it, since the S-280 shelter sits on 3 skids that distribute its 6000 LBS evenly in 3 lines from the front to back of the bed, one at each of left and right edges and one in the center. Could I ditch the mudflap instead and cover the rear of the genset from splashes?

Someone suggested I mount it to the front bumper since it is only 200LBS. I would have to probably mount a couple of "guide sticks" out fron there is I did that so I'd know where the front of the genset is. This mounting would also require that I make an enclosure to keep weather out. If I mount it under the bed, I really only need to protect the side. I never ford, so it should be OK. Anoter person suggested roof-mount, but the hardtop is no way tough enough for that. I would need a custom or reinforced roof. Not sure that is possible with my skills. It can't be mounted to the shelter front because of the air conditioning gear already in place, and also the shelter is not structurally designed to hang things on.

Since this has turned out to be the only practical way to get an onboard power source and still have the truck able to be driven under 13FT clearances, and I am not experienced at this kind of thing, I will hire a welder to make some brackets so the set can slide into place either way and be bolted in.

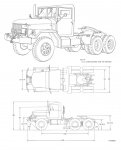

I took the pictures and made up the drawings of the dimentsions and the things under the bed, in hopes that the wizards and gurus here could offer me some sage advice on installing this. At this point I'm open to all kinds of suggestions and would be most grateful, so i can get the job done right the first time!

Well Santa bit the bullet and bought me a diesel genset. This is the smallest one of apparently good quality that he could find. Unfortunately, his note said that even though I had been very good, I'd have to mount it myself!

(the DC power packs at Shirley's seem too wide/long to fit on the truck since the bed is full, does anyone have the TM or dimensions for reference?).

The salesman let me have it for 40% off list ($309

The most desirable goal is to mount it in place of the pioneer tool kit. The overall dimensions suggest removal of the spare tire winch and mount, but the close fit remains to be seen. If the spare goes, then the truck will most likely (prudently) stay a 10-wheeler instead of being singled with taller tires.

The set chosen was the GPNDL-60E from Gillette Generators

http://www.gillettegenerators.com/portable/specs04x.html

which is a 5KW continuous duty (prime, 6KW max.) diesel set. This is enough for powering the S-280 shelter with air conditioning.

Dimensions are 28Lx23Hx20W and mass is 207 Lbs. There was a model GPNDL-40E (4KW/3.5KW prime) which was smaller but is it discontinued due to less demand.

These have Lombardini engines, much better than the Chinese models, having researched and found complaints and parts issues. I have been very afraid of the chinese diesels. Gillette apparently makes the alternators and then integrates the engine and other items into a package.

The genset is 2" longer than the space between the mud flap and the front of the bed. It looks like the best mounting will require me to remove the front brace of the bed corner, that is the large triangular piece at the front of the bed. I don't want to do that but forsee any problems to be caused by doing it, since the S-280 shelter sits on 3 skids that distribute its 6000 LBS evenly in 3 lines from the front to back of the bed, one at each of left and right edges and one in the center. Could I ditch the mudflap instead and cover the rear of the genset from splashes?

Someone suggested I mount it to the front bumper since it is only 200LBS. I would have to probably mount a couple of "guide sticks" out fron there is I did that so I'd know where the front of the genset is. This mounting would also require that I make an enclosure to keep weather out. If I mount it under the bed, I really only need to protect the side. I never ford, so it should be OK. Anoter person suggested roof-mount, but the hardtop is no way tough enough for that. I would need a custom or reinforced roof. Not sure that is possible with my skills. It can't be mounted to the shelter front because of the air conditioning gear already in place, and also the shelter is not structurally designed to hang things on.

Since this has turned out to be the only practical way to get an onboard power source and still have the truck able to be driven under 13FT clearances, and I am not experienced at this kind of thing, I will hire a welder to make some brackets so the set can slide into place either way and be bolted in.

I took the pictures and made up the drawings of the dimentsions and the things under the bed, in hopes that the wizards and gurus here could offer me some sage advice on installing this. At this point I'm open to all kinds of suggestions and would be most grateful, so i can get the job done right the first time!

Attachments

-

35.8 KB Views: 3,312

-

94.6 KB Views: 3,312

-

81.3 KB Views: 3,312

-

87.4 KB Views: 3,309