installing generator on M35A2

First, I must apologize to ichudov, if I offended you about your military surplus generator set. I am sorry, I did not mean for it to read in a negative way. As always, written mesages don't convey feelings or intent well.

I agree about the proper grounding. The set has a place for its own battery, but I will eschew it, possibly using the space later for a spin-on "remote" oil filter. The frame of the set is well-bonded to the set's negative battery wire which is a #2 or #4. I will take this via at least a #0 to the battery box along with the set's +12V battery wire. The AC power ground of the set is also connected to its frame.

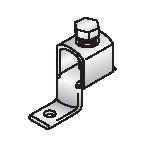

At this point however I may be getting a little short on places at the battery to connect additional wires. I have already added a #6 to the (++), (+), and (-) terminals. I may go up to the next size larger lug. These are not the little things, but are larger size and made of copper alloy. They have a hole for the battery connector's tightening/clamping screw to pass through, and then a part where you put in your extra wires and tighten the heck out of a screw to make the connection.

I may go ahead and solder this additional end up if I upgrade. I have had trouble with clamped wires in filthy places, but never soldered ones. I am using a type similar to the Panduit 644-CB35-36-CY and the larger 644-CB175-38-QY as shown in the picture "lug".

I like these because you can insert the wires and tighten the !!! out of them, and then heat the assembly with a small torch and solder it up. There will -never- be a problem. I have had one on a 100A 28V circuit with a 00 guage wire for 3 years now. This type presses the wire between two copper pieces. Piece #1 is the square-ish box, and piece #2 is the 'tang' section. The pressure squeexing the copper sandwich together is held by the screw. That way, it's all copper-to-copper and a good solder job can be done.

But next, here are pictures of the 1/4" steel plate installed, and the genset sitting in place. I have to relocate one of the 4 bolts holding the plate to the tank mounts but it should not be an issue. before I do anything else, I will do as advised and use a jack to push up on the front mount bending it slightly to make the front end of the plate level with the back. The difference is only about 3/4" with that steel plate there, but I want to straighten this up before going forward. I discovered that the weight of the set on this mount and plate arrangement encourages it to bounce up and down a bit. To combat this, perhaps a piece of 1/2" alltread with a vibrational damper can be used at the outboard edge of the plate to dampen the vibrations, or without, to just rigidly secure the marzal vanes to the layshaft.

The metal plate is positioned so that it is almost as far out from the side as the bed is. This will make it simple later to arrange a hinge and locking side cover plate. The rear edge of the mounting plate stops about 1" forward of the mud flap plane. I will install a sheetmetal shield behind the set to protect it from wheel spray from the front tandem.

In the picture, it can be seen that the genset front frame rail is forward of the front bed plate. I don't have to do any cutting at all, and that's the way i like it. I will have to box forward a splash shield to protect the front of the genset.

The inboard side will be left mostly open to promote cooling air, with any shielding arranged to keep out dirt and (oil or water) spray from the front etc

I have not yet considered the exhaust very much, but by virture of the shrouding of the genset itself, the spent cooling air blows in somewhat of a coaxial manner with the exhaust so as to direct it out away from the side of the truck.

BTW we are having a real windstorm here, 40-60MPH winds kicking up dust so thick it has obscured the sun and grounded planes. The wall of dirt was so great that the radar picked it up. A mini-version of the sandstorms our troops must endure, God bless them.

.