Ronmar

Well-known member

- 4,489

- 8,402

- 113

- Location

- Port angeles wa

I used the included gasket.

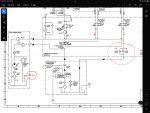

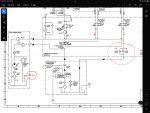

in place of the existing hand pump… Hmmm… Well the existing hand pump is sealed, and the way the valving in the control valve works, it will send all the fluid back toward the hand pump until it develops enough pressure in the sealed reservoir to overcome a 5psi check-valve to start allowing fluid to flow toward the Air/hydraulic pump(First pic). With a vented plug it will eventually overflow… so first step will be replacing the vented filler with a plug. You have to do something with it anyway as the vented plug points straight up and will collect water if the pump is installed out in the weather.

being sealed, the OEM hand pump will actually draw fluid from the AOP reservoir as it does not contain enough fluid in its tiny reservoir to fully lift the cab. I do not know if this pump will pull a vacuum past the control valve on the return side to draw fluid from the AOP reservoir while you are pumping, as the original does. Not a screaming big deal as the hand pump reservoir contains enough fluid to lift the cab, but if it is sealed, all the fluid may not return as the air gap it will create on top by not pulling fluid while pumping, will eventually pressurize and force fluid back to the AOP. So eventually the hand pump reservoir will empty…

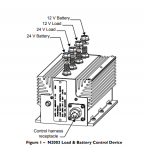

if you are just doing the 2 circuits, cab and tire crane, you could do away with the AOP and manifold entirely and use the hand pump and a selector valve to shift between cab and tire functions(second pic). Then a 2 position 3 way air valve for cab suspension control and you are in buisness…

in place of the existing hand pump… Hmmm… Well the existing hand pump is sealed, and the way the valving in the control valve works, it will send all the fluid back toward the hand pump until it develops enough pressure in the sealed reservoir to overcome a 5psi check-valve to start allowing fluid to flow toward the Air/hydraulic pump(First pic). With a vented plug it will eventually overflow… so first step will be replacing the vented filler with a plug. You have to do something with it anyway as the vented plug points straight up and will collect water if the pump is installed out in the weather.

being sealed, the OEM hand pump will actually draw fluid from the AOP reservoir as it does not contain enough fluid in its tiny reservoir to fully lift the cab. I do not know if this pump will pull a vacuum past the control valve on the return side to draw fluid from the AOP reservoir while you are pumping, as the original does. Not a screaming big deal as the hand pump reservoir contains enough fluid to lift the cab, but if it is sealed, all the fluid may not return as the air gap it will create on top by not pulling fluid while pumping, will eventually pressurize and force fluid back to the AOP. So eventually the hand pump reservoir will empty…

if you are just doing the 2 circuits, cab and tire crane, you could do away with the AOP and manifold entirely and use the hand pump and a selector valve to shift between cab and tire functions(second pic). Then a 2 position 3 way air valve for cab suspension control and you are in buisness…