Hi all - newb here with my first post.

I recently acquired a Fermont MEP-831a from a GovPlanet auction. The unit, with just under 1300 hours, was known to not start, and had numerous fuel leaks. It was also listed as missing some engine parts, although from the auction images the Yanmar L70AE engine appeared complete. I wasn't sure if maybe the inspector was referring to governor/linkage components as part of the "engine assembly".

Having re-plumbed the -4 and -5 (as well as -2 return) lines with correct spec SAE30-10 and/or original Parker hoses, I inspected the rest of the generator, and all appeared intact. I fired her up and she ran, although the governor actuator was notable inactive. I did observe a steady 120V AC displayed on the gauge (frequency counter set to 120V mode). I manually shut her down, and pulled out the governor actuator, at which point I discovered a poor in-field wiring repair which intermittently caused an open-circuit. I quickly mended that with proper soldered joints and Raychem shrink-wrap.

I reinstalled the actuator , adjusted the throttle linkage, and fired her up again. The actuator appeared to hunt quite a bit, and then somethin happened and the AC voltage dropped to 60V AC. I tried to shut off by putting the "run" switch to the stop position. Nothing happened. When I put it back into the run position, the voltage jumped back to 120VAC. However a couple of bands rang out over the moderately noisy engine (backfire-like, but I know diesels don't do that). I thought perhaps a couple of capacitors had blown. Before I could shut her down a mechanical (rubbing-like) sound occurred, and then some smoke poured from the inverter. Sh*t!!!

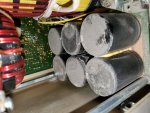

I pulled the inverter and started opening up the enclosure up. So far I can see some discoloration around what appear to be polypropylene capacitors. The logic/control board appears OK as far and no obvious burn marks/etc. It is a seriously-well coated board, no doubt spec'ed for exposure to harsh environments. I plan to take enough apart to get to the power-supply, since I suspect that may contain some electrolytic caps that went "bang".

Anyone with experience rebuilding these feel free to chime in. I will post pics once I am able to, and intend to keep this thread updated as I progress. If anyone has a schematic of the inverter (TRC model 29350 - 60Hz), I'd be grateful for a copy!

-Marcel

I recently acquired a Fermont MEP-831a from a GovPlanet auction. The unit, with just under 1300 hours, was known to not start, and had numerous fuel leaks. It was also listed as missing some engine parts, although from the auction images the Yanmar L70AE engine appeared complete. I wasn't sure if maybe the inspector was referring to governor/linkage components as part of the "engine assembly".

Having re-plumbed the -4 and -5 (as well as -2 return) lines with correct spec SAE30-10 and/or original Parker hoses, I inspected the rest of the generator, and all appeared intact. I fired her up and she ran, although the governor actuator was notable inactive. I did observe a steady 120V AC displayed on the gauge (frequency counter set to 120V mode). I manually shut her down, and pulled out the governor actuator, at which point I discovered a poor in-field wiring repair which intermittently caused an open-circuit. I quickly mended that with proper soldered joints and Raychem shrink-wrap.

I reinstalled the actuator , adjusted the throttle linkage, and fired her up again. The actuator appeared to hunt quite a bit, and then somethin happened and the AC voltage dropped to 60V AC. I tried to shut off by putting the "run" switch to the stop position. Nothing happened. When I put it back into the run position, the voltage jumped back to 120VAC. However a couple of bands rang out over the moderately noisy engine (backfire-like, but I know diesels don't do that). I thought perhaps a couple of capacitors had blown. Before I could shut her down a mechanical (rubbing-like) sound occurred, and then some smoke poured from the inverter. Sh*t!!!

I pulled the inverter and started opening up the enclosure up. So far I can see some discoloration around what appear to be polypropylene capacitors. The logic/control board appears OK as far and no obvious burn marks/etc. It is a seriously-well coated board, no doubt spec'ed for exposure to harsh environments. I plan to take enough apart to get to the power-supply, since I suspect that may contain some electrolytic caps that went "bang".

Anyone with experience rebuilding these feel free to chime in. I will post pics once I am able to, and intend to keep this thread updated as I progress. If anyone has a schematic of the inverter (TRC model 29350 - 60Hz), I'd be grateful for a copy!

-Marcel

Last edited: