Update:

Replaced the 6 Diodes: CR1, CR2, CR3, CR4, CR5, CR6

One thing I noticed on the components which are mounted to heat-sinks is that the original Thermal Joint Compound had completely dried out and provided no more heat transfer.

Some parts of this A11 were manufactured in 1989 week 9:

The Diode Assembly and the VR Board, all other parts were manufactured in the 1970's. So this A11 underwent some maintenance / repair probably in the 90's.

The PCB is fully repaired now except for the Amphenol Receptacle J11. I had ordered a MS3102R18-1SX from Mouser for 25 bucks.

Mouser has the original MS3102R18-1S in stock for 150 Dollars.

I should have checked with Allied Electronics first, they have the original MS3102R18-1S in stock for $ 49.99 (is coming in from Allied today)

The difference between the MS3102R18-1S and the MS3102R18-1SX is the X

without X: machined socket pins

with X: spring loaded socket pins

Those are 18-1

The Mouser MS3102R18-1SX is a Bendix Made in USA, however, the person who assembled those, rotated the insert by app 180 Degrees and now the PIN A is no longer on the side of the connector guide...........

When the Allied Part gets here I can complete the A11 and test it and sent it back.

Note:

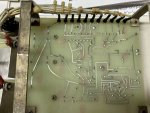

I added solder to the PCB traces. This PCB was made the old fashioned way, silk screening the traces, etching, drilling and then tin plating the traces.

This is a single sided PCB without plated through holes.

At this age, the solder pads will come off the PCB during de soldering a component. To prevent further damage to the PCB, as eventually all traces will separate from the fiber glass substrate, I would recommend adding solder to the traces like in the picture below.

I know this doesn't look beautiful or pretty, but we are trying to restore aging electronics. We are not in it trying to win a beauty contest..........