Hey guys, I was going to make a post with some updates on the passengers side.

BUT I have run into a problem. All the small parts and pieces from the drivers side brake, some of which were just floating around in the drum. I had put them into a can with cleaner to break down all the gear oil "tar" off of them. Just pulled them out of the can and started going through them this morning to finish cleaning them. Under some gunk, I found a pin that is chewed up and wore flat on one side.

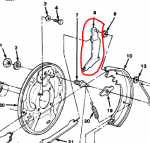

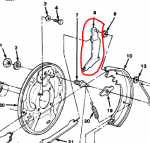

After going through the TM and looking online, I was able to figure out this pin is a part of the "parking brake lever" which connects to the parking brake cable. This pin has what is left of some splines which means it was pressed into the lever, and it is listed and shown as being "one part" in the TM. Here is a photo of the parking brake lever, and the hole on the

left end is where this pin is supposed to be, it's probably "wallowed out" if I had to guess.

**The green solution is Krud Kutter rust remover, which I have it and other parts in right now. It removes rust and leaves a rust resistant coating after the parts are pulled out and allowed to dry. Figured it wouldn't hurt to clean everything up as much as possible.

On the end of the pin, there what the TM lists as "WASHER,SPRING TENSI". I do have that part, it looks like a regular washer, except it is thin and "bowed" to make it into kind of a spring to put tension against the inside of the brake shoe. A new one would probably be good though. There is a groove in the pin where this washer would seat. Don't understand why the AC Delco brake hardware kit wouldn't come with that washer, but there is also two other pieces that are missing from the kit too so...

Parking Brake Lever listed as "8" circled below

(washer is 9) from

TM9-2320-289-34P page

274:

There is two part numbers listed, one is drivers side, the other is passengers side. BUT the TM doesn't actually specify which part number is for which side

. But the two part numbers for the parking brake levers are: 334307 & 334308

[EDIT: Found another site with the same part numbers. Looks like the 334307 is the LH (Drivers side) and 334308 is RH (Passengers Side) LInk to that page:

GM Parking Brake Lever Diagram ]

The "spring washer" is: 5454797

BUT HERE is my problem. This part has been discontinued by GM. AND There does not seem to be ANY OTHER Company that is making replacements. I can't find one on any of the regular parts sites or even Rock Auto. Whether listed as a parking brake "lever" or other part, or by crossing the GM part numbers above.

Anyone know anywhere one could be had? Or any other ideas??

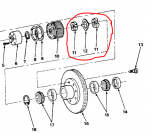

As an endnote, I also found the self adjuster gear was worn and beat up pretty bad, guess from the other parts hitting it. So I'm going to have to order those kits to. So Looks like the truck is going to be sitting for another week... or better. Can install the new races and bearings into the hubs in the meantime. Put races in the freezer, thought it might shrink them just a bit, maybe make it a little easier to install. Especially since i don't have a press.

I would have gotten to this stuff yesterday, but night before last I went into my house and the power was out. Checked main breaker and it was on. Went to the sub box on the pole and the breaker for the line going to my house was

Also On... which didn't make any sense. Turned breaker off as it was late, dark, and raining.

I looked into it yesterday and my Dad came out and wanted to see if he could help, checked power at breaker on the pole was 240v. But power at the main breaker in my house was only showing 7 Volt. So I knew it had to be a short in the line... but still do not understand how or why the breaker at the pole didn't kick out. I told Dad I was going to let it go until next week, as I wanted to get the truck done and thought I was going to have to dig up the whole line which would have taken 2 or 3 days.

In any case, while Dad and I were looking at the line where it goes into my house, the Heavenly Father brought it to my mind to take my voltage meter and stick the prongs into the dirt. I asked my Dad if he thought it might work, neither one of us had ever heard of doing such a thing. But I started up by the house which showed nothing. Then went down to the pole where it was showing about .5 volts. Got about 20 feet from the pole and started getting 10 to 20 volts. Kept testing areas and found the highest voltage showing 68 to 72 volts. So I took my mattock and started to dig, found the wire. I began to pull it up by hand and it broke in half as soon as I pulled on it. I had dug

RIGHT ON TOP of

Exactly where it had Completely Burned in to. Even the ground wire. Couldn't have hit it like that if I had a pro electricians metal detectors and other tools.

In any case, cut both ends off, soldered in a patch wire, and used marine shrink tubing on everything. Put a larger piece of shrink tubing over the entire patch, and then sealed both ends with some rubber hose filled with silicone caulking just as an extra measure. Got power back on yesterday evening. But lost the day working on the truck. Anyway... didn't' mean to get into all that.