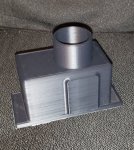

Quick question: the enduser is likely to use progressing grit sandpaper to reduce the print lines, although the original has a rough cast finish on most sides.

Either that or the surface can be smoothed with acetone vapor.

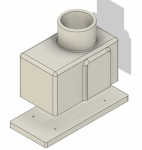

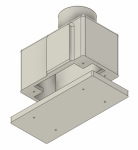

Wouldn't the box itself be better when combined with a 2" x 4.5" x 3/16" thick aluminum base plate to take most of the stress? One can cut one themselves from scrap or go to

www.onlinemetals.com to buy a single piece of aluminum bar stock cut to order.

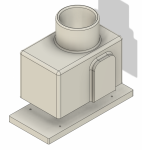

That's an interesting idea. The box's walls are 4 mm thick, which I believe will provide plenty of strength for this application. If something does whack it hard enough to cause it to de-laminate at the layer lines, an aluminum insert can help hold it together. I really have no concept of how strong 3/16" aluminum is - it wouldn't bend easily, would it?

Also, I have been working on my own "pattern" to have the LVOSS main housings cast in aluminum but I no longer live near a metal foundry. I used to be able to deal direct with a metal casting foundry up in Denver, CO but doing test shots and corrections through UPS isn't efficient. Original aluminium launchers fetching $800 + on ebay; the 3D plastic printed ones are subject to weather and UV light that weaken and break down the plastic making them prone to damage.

I'm glad you mentioned the UV degradation. I was originally going to print this with ABS believing that it was actually pretty UV-resistant, but I was mistaken. From what I've read, ASA is a really good plastic for this application, so I'm going to buy a spool of that to use instead!

The main housing would be cast 7071 Aluminum Alloy, cast using a core to form the hollow backside (and to reduce the material cost), so one can install the electrical or pneumatic launch system of their choice. Then 4 individual barrels can be constructed to launch actual smoke signals, or, in my friend's case, to launch pre-rolled T shirts via compressed air during Mardi Gras parade.

Now I want a set of T-shirt launchers for my truck! LOL! I wouldn't mind printing inert replica smoke grenade launchers if I could get measurements of the actual device. They might look nice on the trunk of my Chrysler 200?

Then to protect your parts, there were dust covers made from 1000d Cordura Nylon, to cover all 4 barrels with a hood, to keep birds and insects from making nests in them, to keep rain and snow out, and to stop the whistling as you travel at highway speeds. The original black rubber "condoms" are expensive and hard to find. Sunlight, heat, and UV light all break down the rubber/silicone rubbers in a short time, making them harden, crack then fall apart. Some types of "Armor All" style automotive dressings can be UV resistant to help reduce the deterioration of your rubbers.

If one wanted to make the condoms, I can see making some kind of mold for black silicone rubber that would be UV-resistant. I'd even like to try and make truck steering knuckle zipper boots in that fashion.

Each and every piece of your Restored Military Vehicle or Resto-Modded Military Vehicle are an investment, some pieces have not been manufactured in years or decades or even since WWII. Some parts on your Vehicle can no longer be replaced, originals now Unobtanium. Military Vehicle Parts made from Rubber, Silicone or other Petrol-oil-Gas derivative substances have a shelf life. Many of them begin breaking down the second they are made. This phenomenom seems accellerated since the EPA enviro-nazi movement, you can find plastic polymer or rubber based parts still in the original 1942 made pressed paper box, that are still like new when you take it out of the box. Then others, look at the simple LC-2 ALICE Rucksack, the main flap, the green rubberized underside of the main flap, I've seen rucksacks made from the 1990s on that are otherwise never mounted on a frame or carried by shoulder straps but that flap lining is already gone, peeling away or sticky like honey.

Protect what you can.

Amen!