I wish folks wouldn't post ignorant threads like this.

I didn't see one motor pool in that video. How can you state those were military tires?

Really? No deaths from military tires? None? Are you sure or are you getting awesome, as your avatar says?

https://www.cdc.gov/niosh/face/stateface/ca/05ca007.html

h a testing program and that all training is documented.

[h=3]Introduction[/h] On May 25, 2005, at approximately 11 a.m., a 20-year-old apprentice mechanic died when the tire he was working on exploded. The CA/FACE investigator learned of this incident on June 23, 2005, through the Division of Occupational Safety and Health (Cal/OSHA). Contact with the victim’s employer was made on July 21, 2005. On July 28, 2005, the CA/FACE investigator traveled to the facility where the incident occurred and interviewed the company owner and other employees who were present at the facility when the incident occurred. Pictures of a tire and wheel similar to the one involved in the incident were taken, and the area where the incident took place was examined.

The employer of the victim was an independent water truck rental company which had been in business for 22 years. The company had 22 employees, and three of them were at the facility where the incident took place. The victim, a college student, had been employed with the company for two days, and the lead mechanic he was assigned to work with had been on the job for four days when the incident occurred.

The company had a written safety and Injury and Illness Prevention Program (IIPP) printed in English. The program had a procedure on tire changing that was task-specific for employees to follow. Safety meetings were held twice a year and were documented. The company did not have a documented training program. The training program consisted of employee orientation for new employees that was given by the company owner, and additional training as job duties or work assignments were expanded or changed.

Back to Top

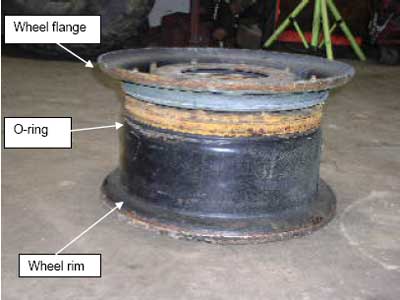

[h=3]Investigation[/h] The site of the incident was an industrial park that housed a one-stall maintenance and repair shop and office that were the headquarters for the company. The tire size involved in the incident was 1,400 x 20. The wheel was two-piece, ten-bolt military rim. This type of wheel requires special preparation before the tire is mounted so that no air leaks will occur once it is inflated to the desired air pressure. All parts and components must be inspected and replaced if defects are found. The rim flange must fit securely once the tire is installed. An O-ring installed around the rim creates a seal where the flange mates with the rim. The nuts on the wheel studs must be tightened in a designated sequence in order to seal against the O-ring. Once inflated, the tire and wheel assembly must be inspected for leaks and if any are found, the tire must be completely deflated before the leak can be repaired.

On the morning of the incident, the owner of the company had demonstrated the proper safety procedure to follow when changing a tire on a military wheel. He then observed the lead mechanic change a tire and made corrections in his technique as needed. Later that morning, the lead mechanic told the victim to check the air pressure in the tire they had assembled earlier that morning, record the pressure on the tire with a grease pencil, and then stack the mounted tire and wheel in the rack. The lead mechanic then went to wash his hands and was walking to the rest room when he heard the sound of a pneumatic impact gun that is used to tighten and loosen the bolts on the wheel. Within a second of hearing that sound, an explosion occurred that shook the entire building. When the mechanic turned around he saw the victim lying supine on the floor. The office manager also came running into the shop when he heard the explosion. The paramedics were called, and they transported the victim to the hospital where he was pronounced dead.

According to the employer of the victim and the lead mechanic, they believe that when the victim checked the air pressure in the tire, he detected an air leak around one of the studs holding the flange and rim together. The sound of the impact gun just before the explosion indicated that he probably was attempting to tighten or loosen one of the flange nuts. Inspection of the wheel studs showed all the threads were shredded off by the bolts when the tire exploded. Further investigation revealed that the wheels and their components were all bought at local auctions. It is not known whether or not the bolts and nuts purchased by the company’s owner were in compliance with the original specifications for the wheel. When the truck and components were bought at auction, they were purchased “as is.”

The safety factor built into most wheels is such that when one bolt should fail, the remaining bolts should be sufficiently strong to keep the wheel together. In this case that did not happen. Without having the original specifications available to ensure proper fit, there is no way to determine if the stocked bolts and nuts were appropriate for this type of wheel.

Back to Top

[h=3]Cause of Death[/h] The cause of death, according to the death certificate, was exsanguinations; lacerations of heart, liver, and right kidney; multiple rib fractures; and blunt force trauma.

[h=3]Recommendations/Discussion[/h]

Recommendation #1: Ensure employees never perform maintenance or repairs on an inflated tire.

Discussion: The pressure inside a tire inflated to 80 psi exerts a force greater than 40,000 pounds against the rim flange. This is why all safety procedures for working on tires recommend always deflating a tire completely before doing any work on it. The general tire safety precautions the employer had for this type of rim specified “never hammer, strike or pry on any type of tire/rim assembly while the tire contains inflation pressure. Do not attempt to seat any part while the tire contains an inflation pressure.” Most accidents involving truck tires with split rims usually occur either during inflation, performing improper procedures as a result of mismatched or damaged components, or a combination. In this particular case, the studs on the rim that hold the flange in place were completely stripped of their threads when the tire exploded. This suggests that wheel components might not have met the original specifications for this type of rim. It is unclear whether this was a factor in this incident; however, the owner of the company admitted that he bought the rim components from an auction, and had no way to verify if they were of the exact specification required for this type of rim. When working with such extreme pressures, exact specification should be met in order to prevent such incidents in the future. When these safety precautions are followed, the chances of another incident occurring are greatly reduced. Employers can enhance worker compliance with safe work practices through programs of task-specific training, supervision, recognition, and progressive disciplinary measures.

Recommendation #2: Ensure new employees are adequately supervised in the performance of their duties.

Discussion: Even though the victim received a job orientation, he had only been on the job two days and was relatively young, suggesting a lack of experience that necessitated closer supervision. The lead mechanic was new to the job himself, and the extent of his supervisory experience is unknown. Employers must pay special attention to supervision of new employees and ensure that those in supervisory positions have the appropriate training and experience to provide oversight to new employees.

Recommendation #3: Ensure that after employees receive specific training, their achievement of skills is verified through a testing program and that all training is documented.

Discussion: Because of the extreme danger and severe consequences of improper handling of tires with multi-piece rims, all personnel working with these types of tires should be well trained in safety practices for work related to multi-piece rims. The employer needs to assure that each employee understands, demonstrates, and maintains the ability to service split and multi-piece rims or wheels safely, including performance of the following tasks:

- Demounting of tires (including deflation).

- Inspection and identification of the rim wheel components.

- Mounting of tire (including inflation with a restraining device or other safeguard required by this section).

- An understanding of the necessity of standing outside the trajectory both during inflation of the tire and during inspection of the rim wheel following inflation.

- Installation and removal of rim wheels from the vehicle.

After training is received, employers need to verify employees’ skills through a testing program. The testing program can be written, oral, or performed, as long as the employer receives verification that the employee has a clear understanding of the training received. [h=3]References[/h]

- California Code of Regulations, Vol. 9, Title 8, Sections 3325, 3326 MN FACE Investigation MN9208.

- https://www.cdc.gov/niosh/99-110.html

Back to Top

[h=3]Exhibits[/h]

| |

| Exhibit 1: A front view of a truck tire mounted on a ten-bolt military wheel similar to the one involved in the incident.

|

| |

| Exhibit 2: A picture of a military wheel showing the rim and flange and O-ring.

|

| |

| Exhibit 3. A picture of a wheel stud involved in the incident showing all the threads flattened by the explosion.

|

| |

| Exhibit 4. A picture of the impact wrench used by the victim.

|

Back to Top

[h=3]California Fatality Assessment and Control Evaluation (FACE) Project[/h] The California Department of Health Services, in cooperation with the Public Health Institute and the National Institute for Occupational Safety and Health (NIOSH), conducts investigations of work-related fatalities. The goal of this program, known as the California Fatality Assessment and Control Evaluation (CA/FACE), is to prevent fatal work injuries in the future. CA/FACE aims to achieve this goal by studying the work environment, the worker, the task the worker was performing, the tools the worker was using, the energy exchange resulting in fatal injury, and the role of management in controlling how these factors interact. NIOSH-funded, state-based FACE programs include: Alaska, California, Iowa, Kentucky, Massachusetts, Michigan, Minnesota, Nebraska, New Jersey, New York, Oklahoma, Oregon, Washington, West Virginia, and Wisconsin.

To contact California State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site. Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

California Case Reports

[h=4]Get Email Updates[/h] Enter your email address to receive new reports/products.

Enter Email Address Enter Email Address

What's this?Submit

[h=5]

Follow NIOSHFACE[/h]

[h=4]Contact FACE[/h] Nancy Romano, M.S., CSHM

FACE Project Officer

Fatality Investigations Team

Division of Safety Research

NIOSH

ndr4@cdc.gov

Press Inquiries

Nura Sadeghpour:

uvg2@cdc.gov

Stephanie Stevens:

yky0@cdc.gov

[h=4]Related Topics[/h]

[h=4]Follow NIOSH[/h]

[h=4]

NIOSH Homepage[/h]