- 2,113

- 563

- 113

- Location

- Davis County, UT

June 20th, 2022:

I noticed the tan generator's fuel return line was very deteriorated, but surprisingly wasn't leaking.

I replaced all the return fuel lines pieces. I had a local place (formerly named "Evco House of Hose" now called "Erik's") match the hose, I think it was 1/8". The supplied hose was a very tight fit on the plastic hose tees and I'm surprised I didn't break any. (I think I didn't at least, I haven't ran the generator much since then).

Short, pointless, video showing the replaced line:

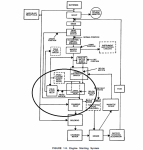

In the MEP-803A-Onan-Engine-DN4M-TM-9-2815-253-24 technical manual, Figure 5 indicates that this plastic hose tee is #4, P/N 186-6177.

In looking to buy a few spares of these plastic hose tees to have as a backup, I saw on eBay that a seller has a brass upgrade version but they don't seem to have very good barbs.

Does anyone know of any other good brass replacement tee options?

(I'm just going to tag @Light in the Dark here for good measure, haha)

I noticed the tan generator's fuel return line was very deteriorated, but surprisingly wasn't leaking.

I replaced all the return fuel lines pieces. I had a local place (formerly named "Evco House of Hose" now called "Erik's") match the hose, I think it was 1/8". The supplied hose was a very tight fit on the plastic hose tees and I'm surprised I didn't break any. (I think I didn't at least, I haven't ran the generator much since then).

Short, pointless, video showing the replaced line:

In the MEP-803A-Onan-Engine-DN4M-TM-9-2815-253-24 technical manual, Figure 5 indicates that this plastic hose tee is #4, P/N 186-6177.

In looking to buy a few spares of these plastic hose tees to have as a backup, I saw on eBay that a seller has a brass upgrade version but they don't seem to have very good barbs.

Does anyone know of any other good brass replacement tee options?

(I'm just going to tag @Light in the Dark here for good measure, haha)

Last edited: