rustystud

Well-known member

- 9,402

- 3,392

- 113

- Location

- Woodinville, Washington

I've been receiving a little interest in the "front servo" upgrade I posted about. I did say it is a drop in installation, but I need to clarify it a bit. You will need to cut off the pipe nut which normally threads into the servo. The later model servos did not use this nut. They just had a straight pipe go into the servo.

This is a picture of the two pipes.

So just cut off the flare end and your Golden !

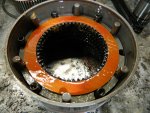

You will also need to plug this hole with a 1/8" pipe plug. Use a 21/64" drill bit and drill down 1/2" . Then tap out with a 1/8" NPT tap.

I installed a stainless steel 1/8" plug here.

I installed a stainless steel 1/8" plug here.

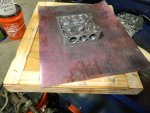

Now you might get lucky if you decide to install one of these servos, but I wasn't so fortunate. It seems this servo can rub against the oil pan housing. I had to take it out several times to "remove" some material so it would fit properly.

This is where it was rubbing, so removing some cast-iron on the servo until I got to the aluminum valve body did the trick.

This is a picture of the two pipes.

So just cut off the flare end and your Golden !

You will also need to plug this hole with a 1/8" pipe plug. Use a 21/64" drill bit and drill down 1/2" . Then tap out with a 1/8" NPT tap.

I installed a stainless steel 1/8" plug here.

I installed a stainless steel 1/8" plug here.Now you might get lucky if you decide to install one of these servos, but I wasn't so fortunate. It seems this servo can rub against the oil pan housing. I had to take it out several times to "remove" some material so it would fit properly.

This is where it was rubbing, so removing some cast-iron on the servo until I got to the aluminum valve body did the trick.

Last edited: