aw113sgte

Well-known member

- 914

- 1,424

- 93

- Location

- La Crosse, WI

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

That hose is called a scavenge and it pulls out the large particles that collect after spinning the air. I would use it if you can.For reference, this is part number D120037. I did look at the flow calcs and the engine recommendations from Donaldson. The filter restriction fitting also screws directly in. Not sure if I will reconnect the aux hose to exhaust... So many other things to do

Yep, I know, just not a high priority as I'm not following conveys or in desert. It will be a very simple thing to do though.That hose is called a scavenge and it pulls out the large particles that collect after spinning the air. I would use it if you can.

Sent from my iPhone using Tapatalk

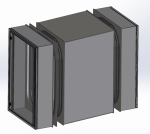

Nice, I have two of those, not sure if I need one or both. Let me know how the engine does with just one maybe I'll sell the other one. I haven't installed them yet still have the original stack.Installed the new air filter. Uses factory rubber boots and intake piping. Plan to have pass through above the filter, right behind the driver.

View attachment 912562View attachment 912563View attachment 912564

Totally depends on size, they have many offerings. What part number do you have and also what engine/power output?Nice, I have two of those, not sure if I need one or both. Let me know how the engine does with just one maybe I'll sell the other one. I haven't installed them yet still have the original stack.

So that exact air cleaner isn't listed in their PDFs, however it has the identical size filter as D100398.I have two PSD100033 NOS which I believe were for an MRAP, and my truck is a 2001 m1083 A1 with the 330 horse 3126

View attachment 912598View attachment 912599

I have two PSD100033 NOS which I believe were for an MRAP, and my truck is a 2001 m1083 A1 with the 330 horse 3126Totally depends on size, they have many offerings. What part number do you have and also what engine/power output?

Answered a few posts up.I have two PSD100033 NOS which I believe were for an MRAP, and my truck is a 2001 m1083 A1 with the 330 horse 3126

View attachment 912598View attachment 912599

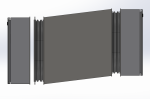

You don’t have to over think it. Just pull the rubber boot off the lip when you need to flip the cab. Takes about 10 extra minutes.Working on the design for the passthrough. Mix between engineering hours, local machine shop capabilities, keeping it KISS.

Planning for door on each side, using some electrical boxes on the ends for that. Need to find a way to support the separation flange when tilting cab(where the gap is right now). What flange fastening method to use...screws, quarter turns, outside vs inside detachment. I do have the geometry sorted though and will have a bit of an angle to put the doors where I want them on each side. Doing a 2.5" offset to clear the hinges on the shipping box door. You can see this in the second image of the overhead view.

View attachment 912739View attachment 912738

I'm not doing that, I flip the cab a lot and pulling that seal, it's grip weakens every time. The whole reason I didn't buy a pre-done RV was because of low quality engineering. I'll make a robust and relatively quick latching mechanism that doesn't get damaged every time it's used.You don’t have to over think it. Just pull the rubber boot off the lip when you need to flip the cab. Takes about 10 extra minutes.

Sent from my iPhone using Tapatalk

can you shoot a pic of this area where bracket/ bolts are at point on the chassis C channel flexing occurred....Went to a nearby park and tested some articulation. Not too worried about tire contact as this only used about 1/2 of available travel. While in this position, I did see flexing of the C-channel box bolt through points at the front and rear of the box. I will be adding springs to the mount points to reduce this stress riser.

I should have taken a picture when flexed as it was more dramatic, but there is still some small amount of plastic deformation in the area of the forwardmost bolt shown. None of the others have any plastic deformation. I have ordered springs, bolts, washers for all 30 tie in locations to replace these relatively rigid mounts.can you shoot a pic of this area where bracket/ bolts are at point on the chassis C channel flexing occurred.

thanks in advance

.I should have taken a picture when flexed as it was more dramatic, but there is still some small amount of plastic deformation in the area of the forwardmost bolt shown. None of the others have any plastic deformation. I have ordered springs, bolts, washers for all 30 tie in locations to replace these relatively rigid mounts.

View attachment 912920View attachment 912918

View attachment 912921

I am an engineer.

am not an engineer.. looks to me though that angle iron is not up to the task though. WIder and ton of triangulation ribs needed??

what about using magnetic force to close that connection from the cab for cab tilt?I'm not doing that, I flip the cab a lot and pulling that seal, it's grip weakens every time. The whole reason I didn't buy a pre-done RV was because of low quality engineering. I'll make a robust and relatively quick latching mechanism that doesn't get damaged every time it's used.

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!