I finally got the landing lights wired up.

So here's the run-down:

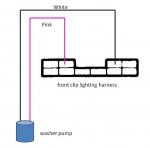

8 gauge wire from the 24V bus bar- a very short run to the fuse.

8 gauge wire from the fuse to the solenoid.

8 gauge wire from the solenoid to just shy of the lights, where it splits into two 10 gauge wires, one to each light bucket.

Two 10 gauge ground wires to one 8 gauge wire in the reverse configuration to ground back at the bus bar. The looming of the wires will have to wait until another day. All connections are crimped and solder-filled to keep water out, then covered with heat-shrink.

Pic 1: 40 amp fuse as close to the bus bar as possible.

Pic 2: The solenoid, triggered by 12V.

Pic 3: Almost there!

Pic 4: Lights on!

They worked great, and darn near set my pants on fire as I was doing some preliminary aiming against the garage door. Those bulbs get HOT. I turned all the forward firing lights on for the last picture, and noticed that even with the truck running the voltage gauge was at the very bottom of the green range. So they're moving some serious current.

After I shut them off they wouldn't come back on. Did the 40 amp fuse blow? Nope, it was the solenoid that failed. It was screaming hot. So I need to swap the solenoid out for something a little heavier. I'll probably swap in the same solenoid I used for the doghead starter relay mod.